The effect of animal feed processing technology on feed nutrition

With the continuous research of animal and feed nutrition by experts in the breeding industry and nutritionists, feed processing technology has made great progress, and feed production factories' requirements and awareness of animal feed production have also been significantly improved. As a result, the nutritional indicators required for animal feed in the world have been introduced into China, and some new feed processing techniques have been introduced into China and improved and extended. Choosing the appropriate animal feed processing technology is conducive to the development of the breeding industry.

1. Feed processing technology

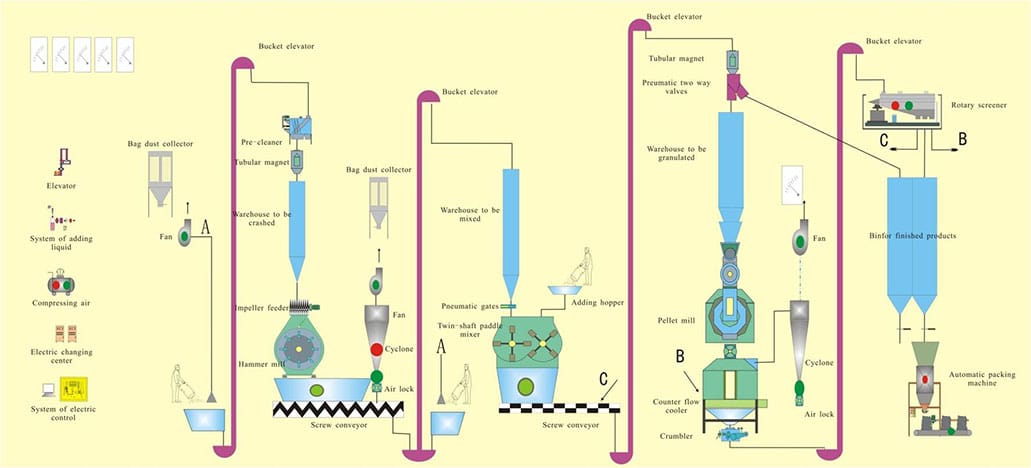

The specific animal feed processing technology is mainly defined by the academic circles as two types. The first type: specific processing of ingredients after the raw materials are crushed. The second type: during the preparation process, the ingredients and raw materials are matched in a certain proportion and then crushed. In some cases, a mixture of two processing techniques will be adopted to meet specific nutritional needs. In the mixing process, the main indicators that affect the nutritional content of feed and animal production performance include mixing uniformity, crushing particle size and other indicators, as well as granulation and expansion.

2. The effect of mixing technology on animal feed production process and main feed indicators

(1) The relationship between mixing principle and mixing uniformity

Currently, Chinese feed mill plants mainly use mixing methods such as impact, convection, shearing, crushing, and diffusion. The movement of the raw materials under the drive of the mixer rotor determines the feed mixing mode. For example, a certain gradient formed between the rotors causes the mixture to be cut in a tangential manner to produce a shear mixing mode.

(2) The influence of mixed mode on feed production and main indicators of feed

International surveys on animal nutrition show that high-uniformity feed will increase animal productivity and feed absorption rate. In order to maintain the uniformity of the feed in most feed production processes, certain chemical substances are added to maintain the energy of the feed. Among them, the chemical substances will destroy the animal's body and affect the animal's production performance. The conclusion of the study on mixed feed for pigs is: low uniformity feed can significantly slow down the growth rate of pigs. The decrease in ketone secretions in pigs is significantly reduced.

(3) Factors affecting the uniformity of mixing

The factors that have a certain influence on the uniformity of mixing are: the model of the mixer and the speed of the rotor of the mixer, the mixing time of the feed and the filling number and the filling coefficient in the calculation formula, in the specific mixing uniformity During the analysis process, the influence of the wear of the animal feed mixing machine on the uniformity also determines the quality of the feed.

3. The impact of crushing on animal feed production process and main feed indicators

(1) The effect of crushing particle size on feed nutrition and animal performance

The crushing of raw materials will increase the area of raw materials, increase the chance of animal digestive enzymes contacting feed, and promote the digestive efficiency of animals and the absorption efficiency of food nutrients. The increase of the crushing particle size can improve the nutrient utilization of feed and the nutrient intake of animals. Since different animals have different requirements for crushing particle size, the appropriate crushing particle size has a corresponding impact on the efficiency of the production process. In the selection process of the specific animal feed crushing machine, the animal feed hammer mill crushers can crush the feed with the greatest strength and improve the efficiency of feed crushing. Appropriate feed mill is helpful to improve the absorption of nitrogen in feed by animals. The specific twist adjustment of the animal feed hammer mill grinder machine should also be adapted to different animal feed production. The animal feed grinding machine for making broilers chicken feed should be adjusted at about 700nm, but the gain corn feed grinder equipment for egg stage should be adjusted at about 400nm.

(2) The best crushing particle size of finished feed

When determining the crushing particle size of a certain feed product, adjust it according to different animals and their eating habits. In the process of determining the corresponding optimal crushing particle size, our country has investigated several animals. According to the national standards, the size of the chicken feed during the laying period is about 4mm, the size of broiler feed production is about 5mm, and the size of piglet feed production is about 10mm.

4. The effect of pelleting on feed production and main feed indicators

In the related investigations of feed production, it is shown that pelleting has an impact on the manufacturing of feed: a certain pelleting is beneficial to improve the digestibility of elements by animals and promote the nutritional structure of feed. At present, there are two main forms of pelletizing feed in animal feed manufacturing process. One form is to use melted starch to wrap the feed to facilitate the decomposition of the feed by the animal. The other is to use hydration and heating to destroy the original protein space of the starch in the process of making the feed to improve the digestibility of the animal. Both of these methods of pelleting will have a certain impact on the nutritional content of the feed. The pelleting of feed is beneficial to the hydrolysis and absorption of feed by animals, and the absorption of amino acids and trace elements has been upgraded to a new level. Pelleting the feed will generally improve the performance and vitality of animals.

5. The influence of extrusion on the production of feed and the main indicators of feed

The expansion of feed can improve the digestion rate of amino acids to a certain extent. The expansion of the feed increases the protein content of the feed itself, which can promote the physiological metabolism of the animal itself. In the research and investigation of feed expansion at different temperatures, it is shown that the use of heat-expanded feed will reduce the probability of animals with diarrhea in daily life and improve the function of the animal's body. The analysis of animal serum extracts also showed that the utilization of nitrogen has been significantly improved after expansion.

【Related info about animal feed production process】

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.