How to Control the Moisture Content of Cattle Feed Pellet in Cattle Feed Line Production?

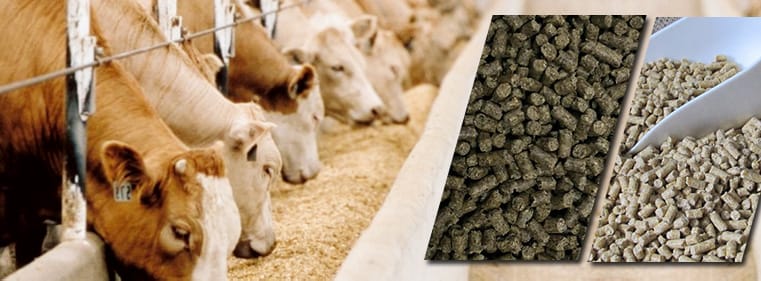

The moisture content of cattle feed pellet is a very important quality index, it affects the quality of feed pellet directly. If moisture content more or less than the stipulated standard, cattle feed pellet will be easy to mildewed and nutrients will be reduced. When produce cattle feed pellet, suitable moisture content will be good for producing,reduce moisture energy consumption and improve productivity. Moisture content control is in the whole cattle feed line production process, according to the different situations comprehensive control various factors.

1.What affect the moisture of cattle feed pellet?

(1)The moisture content of cattle feed making raw material

Ensure the accuracy of detection when detect the moisture content of raw material for cattle feed. To reduce errors, we can detect two or three parallel samples to get an average value to be the detection value. The raw material who has high water absorption like rice bran, it needs add base plate when stacking.

(2)In the pelleting process

The ring die of cattle feed pellet milling machine has different aperture sizes, so the feed pellet products have different moisture content. Using the small aperture size circular mould, then the feed pellet has small diameter, and the pellet will has less moisture. But use the large size ring die then the cattle feed pellet has large diameter, and the produce has more moisture content.

(3)In the cooling process

Cooling is the last link of process. In the cooling process, the first thing is that ensure the moisture content can't above the quality control standard. Then, control a suitable temperature. Ensure the products will not has bad influence because of the high temperature.

(4)Packaging and store

It is also very important to manage finished products. Usually, the temperature of feed pellet can't above the room temperature. It had better avoid direct exposure to the sun after packaging. If not, the moisture of pellet will migrate to the place where has lower temperature, and then the cattle feed pellet will get mildewed easily.

2.How to control the moisture content of cattle feed pellet?

(1)In the actual cattle feed plant manufacturing process, if the powder material has lower moisture content, we need reduce the steam pressure and close all traps to improve the moisture content of feed pellet. If the powder material has higher moisture content, we need use the high pressure over-saturation steam to control the moisture.

(2)Cooling process is to reduce the temperature of feed pellet, and control the moisture content of cattle pellet to get the stipulated standard. Until the temperature and moisture of cattle feed pellet get the requirement, we can pack the cattle feed pellet. If not, the finished products will be mildewed easily. We should according to the output, temperature, moisture of feed pellet to adjust the quantity of wind. If the cattle cow feed pellets are too dry and small, we should reduce the quantity of wind, and cooling time should shorter than normal. If not, increase the quantity of wind, and take more time to cooling. Ensure the pellets get the same cooling time, and operate strictly according to the operation requirement of the cattle pellet cooler.

(3)If the raw material has lower moisture, adding atomized water when mix the material can improve the quality of cattle feed pellet, reduce power consumption, and improve the economic benefits. The moisture content of feed pellet is affected by the raw material, store, and each production processing link in the process of producing, so the moisture control must be strengthened.

3.How to make cattle feed process with details?

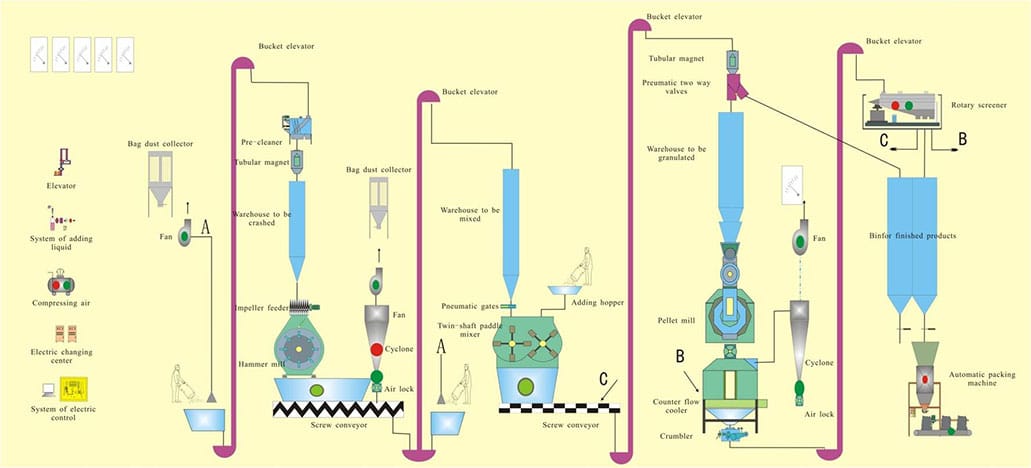

(1)Raw Material Reception and Storage

Cattle feed raw materials vary, they include: long material like crop straw, grains like wheat, maize, and others like oil cake/meal, additives, etc. different raw materials have different storage methods. For example, in complete cattle feed pellet manufacturing line of large capacity, storage silo is necessary for storing maize, wheat, and other grains.

(2)Feed Material Cleaning

The impurities in feed raw materials not only affect the quality of cattle feed pellet products, but also directly relate to the cattle feed processing machines and personal safety. In serious case, the whole cattle feed equipment can be destroyed, which impacts the smooth progress of the feed production, so the impurities must be removed in time. The cleaning equipment of the cattle feed pellet production line is based on screening and magnetic separation equipment. Screening equipment is used to remove large and long impurities such as stones, mud blocks and sacks. The magnetic separator is mainly used to remove iron impurities.

(3)Feed Raw Material Crushing

The technological process of feed crushing is determined according to the required fineness and the variety of feed. According to the times of raw material crushing, it can be divided into one stage crushing process, circulation crushing process or two stage crushing process. According to the combination form of batching, it can be divided into first batching, then crushing and first crushing then batching technology. Cattle feed grinder hammer mill is the most commonly used machine in this process.

(4)Feed Material Batching/Proportioning Process

At present, the commonly used batching processes include manual batching, volumetric batching, one warehouse one scale batching, etc. Manual batching is mostly utilized in small cattle feed pellet making plant and medium scale cattle feed mill plant factory. In this batching technology, all feed materials are weighed manually by workers and poured into the mixing machine. As the whole cattle feed line manufacturing process like measuring and proportioning is all operated by manpower, it needs less cattle feed equipment investment and low production cost, and has flexible and precise measuring.

(5)Feed Mixing Process

There are 2 feed mixing methods: batch mixing and continuous mixing. Batch mixing is to blend all the components together according to the proportion of the cattle feed making formula, and mix them in the periodically running "batch mixer". This mixing method is convenient for replacing cattle feed pellet formula, and the intermixing between each batch is less, so batch mixing is commonly applied at present. However, as the start and stop operation is complex, the automatic program control is mostly used.

The continuous mixing process is a continuous measurement of all kinds of feed components at the same time respectively and proportionately matched to a stream containing various feed components. When the stream enters a continuous cattle feed mixer, it is mixed continuously into a uniform flow of material. The advantage of this process is that it can be carried out continuously, easily with comminution and granulation, so the production does not need to operate frequently. but when changing feed formula, the adjustment of the flow is more troublesome and the material residue in the continuous conveying and continuous mixing equipment is more, so the intermixing problem between the two batches of feed is more serious.

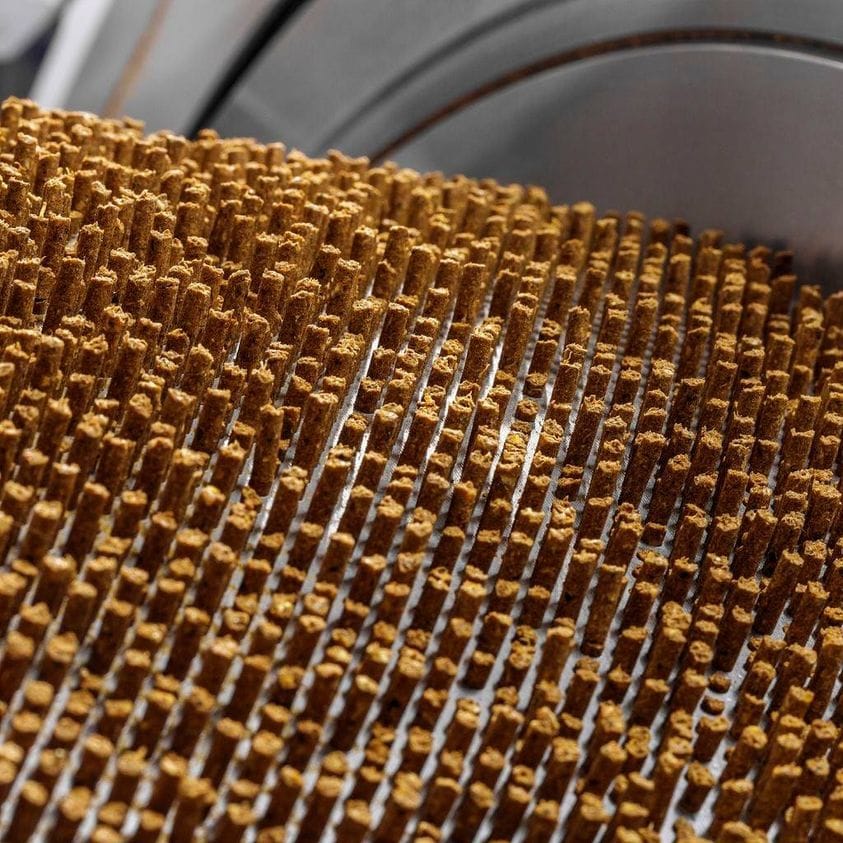

(6)Cattle feed pelletizing

In cattle cow feed pellet processing factory, cattle feed material conditioning (tempering) is necessary, so ring die cattle feed pelletizer machine is usually equipped with a conditioner on the top. The conditioning result directly influences feed pellets quality. The purpose of conditioning is to add water to the feed powder to let it has certain moisture content. After conditioning, the feed material is distributed evenly between the roller and ring die, so the feed pellets are pressed out through ring die holes, cut and discharged.

(7)Feed Pellets Cooling

As in the process of cattle feed pelletizing, the cattle feed is input high temperature and humidity steam, and the squezzing process generates great heat, so the feed pellets moisture content can reach 16-18%, and temperature reach 75 ℃-85 ℃. Under this condition, the feed pellets are easily deformed and broken, and would bond and mildew in storage, so it is necessary to use cattle feed pellet cooler to reduce their moisture to below 14% and decrease the temperature to below 8 degrees Celsius.

(8)Feed Pellets Crumbling

For making young cattle feed pellets of small size, crumbling is also necessary. In order to save electricity, increase the output and improve the quality, the feed material is often made into a certain size pellets in order to save electricity, and then broken into required smaller pellet size. But it is not a must for all cattle animal feed production factories.

(9)Sieving (Screening)

In small cattle feed pellet making plant, this process is realized by the cattle feed pellet cooler. But in larger capacity medium feed pellet line, if the crumbler is used, the pellet sieving machine is also needed, since it can separate the powder from eligible feed pellets, so that uniform feed pellets can be deliver to later packaging process, and the powder or uneligible feed pellets can go back for reproduction.

(10)Feed Pellets Packaging

Finished cattle feed pellets are weighted and packaged for sale on the market.

The above cattle feed plant processing flow is suitable for 1-100 tons per hour complete cattle feed processing plant , please feel free to consult and quote for starting cattle cow feed production business!

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.