Why extruded feed is becoming more and more popular?

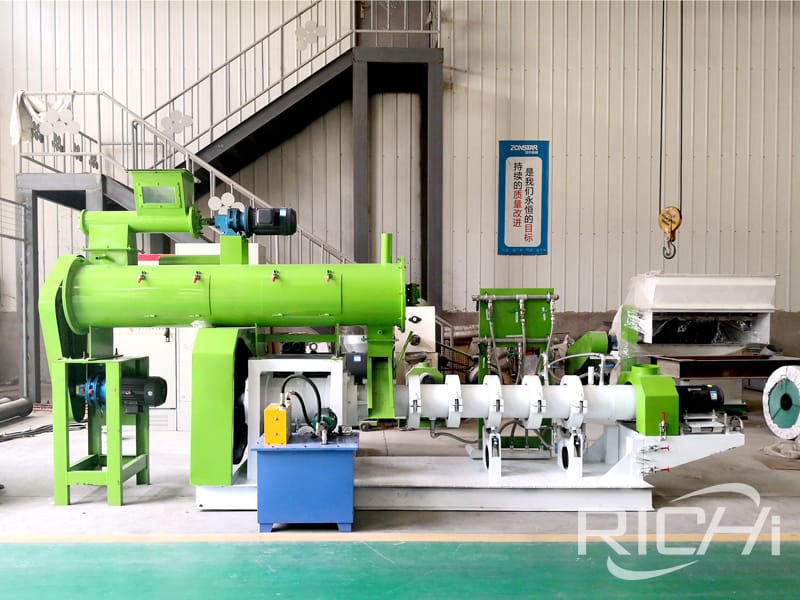

The animal feed extruder machines are mainly used for producing aquatic feed,extruded full fat soybean,pet feed,ornamental fish feed and extruded suckling pig feed.Using extrusion technology to process animal feed has many advantages than other processing methods.

factory price extruder for animal feed :

(1)feed extruder machine,capacity : 2t/h,main power: 132kw

(2)DSP feed pellet extruder,capacity 3-4t/h,main power: 132kw

(3)Wet type fodder mill extruder,capacity : 1-1.2t/h,main power: 75kw

(4)Dry type fodder mill extruder,capacity : 0.12-0.15t/h,main power: 15kw

1.Aims of extruded feed

(1)Curing

Material is total curing in 10 seconds,the required temperature is generally between 120℃-175℃ according to different material. The curing function of extruder basically relates with growth inhibitory factor which destroys grain. This device can complete processing in the absence of oxygen and a very short time. To be helpful for the preservation of protein, energy and vitamins, reducing the product browning due to oxidation and improving the product digestibility and palatability.

(2)Sterilization,Detoxication

The high temperature and pressure generated when the extruder is operating, inhibiting Salmonella,Escherichia coli and other similar harmful substances effectively. Beyond doubt,the extrusion can also be applied to the waste of slaughterhouse,destroy the waste toxins or reduce to within the animal acceptable safety range.

(3)Extrusion

Material after the continuous high-pressure and curing, sudden release of pressure can cause gelatinization of starch cells, rupture of oil cells, becoming the products what we need in this state.

(4)Mixing, Grinding

Most of materials before the extrusion has been rough grinding and pre-mixing, through the friction and shearing action of the screw and resistance circle in the extruding chamber, make materials further mixing and crushing,which is helpful for the homogenization of the final product.

(5)Dehydration

In some cases, 50% moisture of materials will evaporate with the high temperature of extruding chamber, which is very useful for storage.

2.The characteristics of extruded feed:

(1)Palatability

With the advantages of unique fragrance and puff,good palatability and high degree of gelatinization.

(2) Good for health

The extruded feed through higher temperature and pressure than pelleting,large numbers of feed disease-causing microorganisms are killed, preventing the pig white scour,yellow scour and edema effectively to improve the survival rate of cubs, which is benefit for the health of livestock and poultry.

(3)Help absorb

Short-term high-temperature, high pressure and curing can reduce the urease activity of materials, kill the anti-nutritional factors, destory cellulose of feed, α-amylase, nutrients of feed are more helpful to digestion and absorption of livestock and poultry, improving the feed utilization rate.

(4)Improve energy

Make full use of feed resources. The pellet feed because of characteristics of ring die , so it is difficult to produce high-fat feed and strict with the moisture of feed raw materials. The extruded feed is produced by the extruder, relax the requirements of fat and moisture, produce high-energy feed, fully meet the needs of livestock and poultry fattening.

(5)Remarkable benefits

According to the research of domestic and foreign specialists, showing that the extruded feed compared with pellet feed, the ratio of feed may be lower 8-10%. This will reduce feed cost, shorten the fattening time and bring greater economic benefit.

3.Customize your feed production processing line:

(3)Shrimp feed processing line

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.