The influence of inferior ring die for animal feed pellet mill machine

With the rapid development of feed industry,animal feed pellet production line has covered all over the world,the animal pellet feed has become the main products to promote the development of animal agriculture,meanwhile RICHI ring die pellet mill is popular in domestic markets and sold best in international markets.

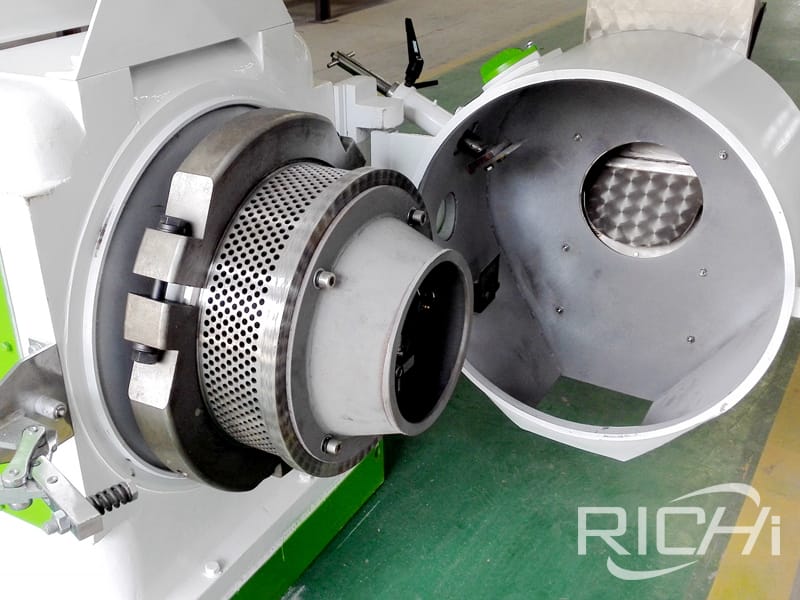

Currently,because of the popularity of animal feed processing plants and increase of pellet feed production, so inferior ring die produced by some small factories has flowed into markets,some feed pellet manufacturing plants attracted by low price,but inferior ring die is rough processing, the useful life is short and the most important is shortcomings of the low copy accuracy,poor concentricity and big beating of ring die working surface.

According to recent investigation from after-sale services office, the feed pellets plants use non RICHI original ring die, parts will appear various degree of wear after pellet mill equipment operates several months,high frequency of bearing wear and serious oil leakage of oil seal. The main engine often has malfunction,causing pellet mill operates unsteadily and low capacity. This is actually like the copycat mobile phones in the market at present. Although the price is only one-third of brand mobile phones, but the radiation damage of minds is more than five times, reason is the same. Why use inferior ring die will shorten the useful life of ring die feed pellet making machine? There are many reasons for low cost-effective .

1. The inferior ring die is in pursuit of low price sales, so it has certain limitation in the blank selection, it's impossible to use high quality material, only select low price inferior billet as raw material, the molecular structure of this billet is not tight, the tenacity can't reach the requirement,poor abrasion-resistant , the ring die made of this billet is with short useful life and easy to crack.Select such ring die, not only waste money input for replacing mould frequently, to be worse is existing potential safety hazards in the production.

2. The rough processing equipment of inferior ring die ,it is impossible to solve the accuracy of inside and outside circle of ring die processing as Zhengchang. At present, general ring die manufacturers in precise machining of ring die,most use old lathes, equipments are relatively old, the machining accuracy can't reach the requirement and ring die is imitative,major fitting face accuracy and finish size is difficult to ensure accuracy,like joint surface of ring die and encircled hoop. Only 0.1mm error,the encircled hoop doesn't hold ring die tightly, causing ring die to shake and rub when pellet mill operates at high speed, the encircled hoop and the hollow shaft drive wheel damaged at the same time, and the body of pellet feed processing machine appears vibration.

3. The die hole processing technology of pellet mill ring die is very particular, RICHI ring die drilling hole equipment uses imported gun drilling, with the advantages of die holes are in order,hole wall is as smooth as the mirror and so on. But the inferior ring die holes are mostly made by manual operation of small drilling machine. Hole inner wall with rub is rough ,the compression ratios of ring die are in various shades, causing difficult discharging of ring die, block die and machine easily , increasing the consumption of electricity, the capacity is reduced, the appearance of pellet is unsmooth, finished materials are uneven in length. Especially when granule feed pellet mill machine is blocked, the temperature of chamber increases rapidly because of ring die extrusion. The pressure roller and main shaft bearing is easily burned out, increase the working load and quicken the wear of big and small gear of feed pellet manufacturing machine.

4.Quenching technology is an important part of the ring die manufacture, RICHI ring die quenching technology is very particular, all use USA vacuum quenching furnace and Japan multi-purpose quenching furnace. Currently small ring die feed pellet processing plants are difficult to have such advanced feed equipment,generally use the indigenous method of pit quenching furnace, this device doesn't control the quenching temperature of ring die automatically, causing the hardness of ring die outside and inside after quenching is inconsistent, moreover the deformation coefficient is big, ring die loses roundness easily.

Animal feed pellet machine uses this ring die,the pressure roller can impact on the ring die frequently in the operation, causing the shaking noise of pellet mill to increase, also is the important factor of the damage of main shaft and race rotation,once the bearings of main shaft and hollow shaft are damaged or run inner and outer rings, the main shaft and hollow shaft may be scrapped,if the bearing bore of main engine case is worn , not only cause fodder pellet machine to operate powerlessly, the output decreased significantly, but also cause animal feed pellet mill machine can't operate normally.

5.The processing of inferior ring die is mostly imitative, the machining accuracy is uncontrollable, in addition, error accumulation in all respects. Use this ring die in long-term, seriously affect pellet mill operate normally. Pellet mill can't reach the purposes of safety, high output and low consumption at all. Count the account carefully, although the price of inferior ring die is cheap, spare parts and bearing replaced frequently,the output decreased,the electricity consumption increase and the waste of manpower affects economic benefits of the enterprises. To make your pellet mill in the feed production achieve the purpose of high quality, high output, low electricity consumption and production safety.

Bring the animal feed pellet making machine efficiency of work into full play, it is the best to use high quality standard ring die of RICHI original.

RICHI Ring Die Animal feed pellet making machines

1-2t/h SZLH250 small sized farms animal cattle pig fodder pellet making machine

3-4t/h SZLH320 animal feed pellet mill

5-7t/h SZLH350 feed pellet making machine

8-12t/h SZLH420 China Pellet Mill

10-18t/h SZLH508 china supplier poultry farming feed pellet mill

15-25t/h SZLH558 animal food pellet making machine

20-30t/h SZLH678 china supplier animal pellet mill

25-40t/h SZLH-768 ring die animal livestock horse goat duck dog cow prawn pig feed pellet mill

28-45t/h SZLH858 ring die animal poultry rabbit aqua fish shrimp feed pellet mill

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.