How to process grass pellets with a good quality grass pellet press machine?

How to process grass pellets with a good quality grass pellet press machine?Grass pellet as a kind of biomass pellet, it has wide application and unique advantages. The market demand for the grass pellets is enormous. So can we make the grass pellets by ourselves? The raw material is easy to get, how can turn waste to the wealthy? Today, we would like to introduce the method to make grass pellets.

1.Advantages of grass pellets

At first, we need to have an understanding of the grass pellets. Nowadays, many raw materials can be made to the pellets. The grass pellets as a fuel have been a well-accepted method in Europe for a long time. Not only be a fuel but as the feedstuff, the grass pellets are an excellent choice.

(1)As biomass fuel pellets

Burning grass pellets as a biofuel is economical, energy-efficient, environmentally friendly and sustainable. The grass pellets have been accepted by the majority of people. As a clean fuel, more and more people prefer to choose grass pellets because the raw material is cheap and easy to get.

(2)As animal feed

Besides, the grass pellets can be the feedstuff for many animals like horses. As the feedstuff, the grass pellets can be fed as partial hay replacer and they have much nutrition elements.

Grass pellets have great potential as a low-tech, small-scale, renewable energy system that can be locally produced, locally processed and locally consumed, while having a positive impact on rural communities. For each family,each farm,each feed processing plant, they can make the grass pellets if they have a pellet mill to operate. The raw material is easy to get, and the small pellet mill is easy to operate, so it will be a trend as soon as possible. How can we make grass pellets?

Compared with biomass pellet fuels such as wood pellets and straw pellets, grass pellets are more used as animal feed.So today's content is all started with the processing method of grass pellets as feed.

2.Raw material for grass pellets

Feed is the material basis for the development of animal husbandry. The feed animals raised are different, and the choice of forage grass is also different. The nutritional value of each feed animal is different. According to, cold resistance, drought resistance, disease resistance, high yield, palatability, etc., select some good varieties suitable for planting in different regions.

Forage grass not only contain various nutrients necessary for poultry, but also contain crude fiber that is particularly important for maintaining the health of ruminant livestock. This is irreplaceable by food and other feeds. High-quality forage can fully meet the nutritional needs of general livestock. Many experiments have shown that if the quality of forage is too low, no matter how much concentrate is added, the milk production of cattle will show a downward trend.

Under the condition that the concentrate is unchanged, the high-quality alfalfa hay replaces the low-quality forage grass such as wheat straw, rice straw, etc., and the daily milk output has been significantly improved. For cattle and sheep during fattening period, when the proportion of concentrate is unchanged, the quality of hay is improved, and the effect of weight gain of livestock is significant.

Forage grass is the cheapest source of feed for livestock. Compared with food crops, the cost of feeding grass with livestock is much lower. There are many types of forage, and the most important condition for selection is forage that has high nutritional value for livestock and improves the meat quality of livestock.

3.Process of making grass pellets

(1) For home-made grass pellets,you just need a small grass pellet mill

You need to choose the suitable grass pellet machine according to our requirements. As a grass pellet mill manufacturer, RICHI suggests four types small pellet mills for you to choose. you can choose the most suitable one to depend on the physical truth.

After you have chosen the suitable pellet mill, you can begin to make your own grass pellets. The key technology of making grass pellets is adjusting the moisture of the grass. The best moisture of the grass pellets is between 13%-16%. So you should adjust the moisture of the raw grass. You can dry the grass in the sun for a day or use the dryer to do that.

Then turn on the pellet mill and put the processed grass pellets into the pellet mill, then the pellet will begin to work. The raw material will enter the working room. The flat die or ring die will grind the grass and squeeze the raw material into the hole. And the raw materials are formed into the cylindrical preliminarily. After that, the grass cylindrical will be cut, formed pellets, and the dump tray sends the grass pellets out. Then you just need to wait for your grass pellets!

When you use the pellet mill, you should read the pellet mill operation guide first. When you first use the pellet mill, you need to turn on the machine and put into the woods, sands, oil in a certain ratio to break in that can prolong the service life of the pellet mill. Besides, if you have any questions when you use the pellet mill, you also can contact us. RICHI provides the professional service and worker for our clients. We provide the 7/24 e-mail service for you!

(2)For feed pellet production plant,you need a complete ring die grass pellet production making plant

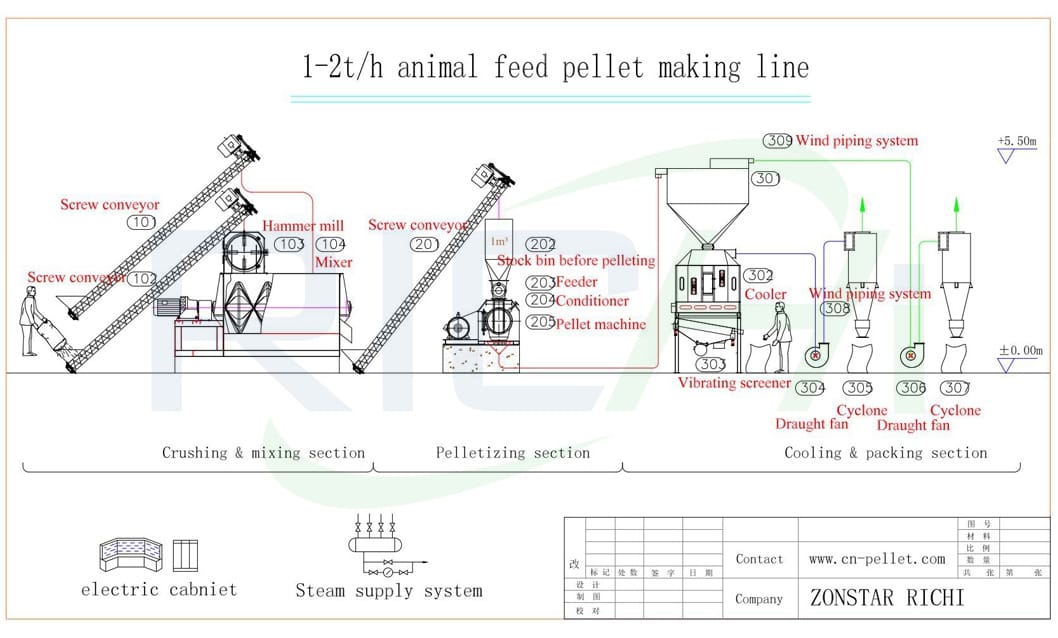

The process of grass pellet manufacturing was first developed for the livestock feed industry. It can be said to consist of a few basic sub-processes: grinding of alfalfa grass, drying, pelletizing and cooling.

The raw grass is first freed from heavy contaminant (rocks, metals and other foreign material), and then grinded in a grass hammer mill or a chipping machine. The particle size is adjusted to a uniform maximum dimension, which is approximately 85 % or less of the minimum thickness of the pellet to be produced. The often high moisture content of raw alfalfa makes drying necessary. The product from the grass crusher is transported to a dryer (generally a rotary drum type one) where the moisture content of the uniformly dimensioned particles is reduced to about 10 % (w.b.).

Then, grass particles can be conditioned, i.e. steam or organic binding agents can be added (according to legal specifications). After conditioning, the particles are then moved by conveyor to a pellet mill, where the pellets are extruded through the action of rollers acting on a perforated matrix. On the outer side of the latter, a knife cut off the pellets at the desired length. Residual moisture in the feedstock turns to steam during compression and helps lubricate the compression die. After extrusion, alfalfa pellets are very hot (90-100°C) and are immediately air quenched down to 25°C. This sets up the lignin and hardens the product, and contributes to maintain its quality during storage and handling.

Finally it is screened, so as to separate the residual fines which are generally re-used in the process. Dust free alflafa pellets are then ready for storage (in a silo) or for automatic packing (in 25 kg bags or big bags – 1 to 1,5 m³).

In the second step in alfalfa pellet processing, there are two main types of pellet presses: flat die and ring die types. The flat die grass pellet mill have a circular perforated disk on which two or more rollers rotate and force the material through the holes. The ring die press features a rotating perforated ring on which rollers (normally two or three) press on the material to the inner perimeter.

The final processed grass pellets can be used as animal feed, mainly cattle feed,sheep feed,horse feed. Using products as forage for young cow/sheep/horse is very beneficial because it is much more digestible compared to grass hays.

4. The key to the processing technology of grass pellets

(1) The most critical technique for processing grass particles is to adjust the moisture content of the raw materials. The water content of the raw materials must be measured first, and then mixed with water to the required water content for processing. According to the determination, the optimal moisture content of legume forage grass particles is 14% to 16%; forage grass forage is 13% to 15%.

(2) The processing of grass pellets usually uses pellet feed pellet machine. The grass powder is stirred and squeezed during the granulation process. Under normal circumstances, the temperature of the granules just coming out of the sieve hole is about 80°C, and the water content is generally reduced by 3% to 5% from the high temperature to room temperature. Therefore, the water content of the grass particles after cooling does not exceed 11% to 13%. Because the water content is very low, it is suitable for long-term storage without mold and deterioration.

(3) The processing of grass particles can be made into grass particles containing different nutrients according to the nutritional requirements of various livestock and poultry. The particle size can be adjusted by the granulator and processed as required.

5. Examples of ingredients and effects of grass pellet feed

In order to produce compound feed for various livestock and poultry, improve feed utilization. The compound feed is composed of grass powder (green hay, crop straw) 55%-60%, concentrate (corn, sorghum, oats, bran, etc.) 35%-40%, minerals and vitamins 3%, and urea 1%. Pellet feed is compressed by pellet feed press. When pressing, 17 kg of water is added per 100 kg of material, and 100 ml of 37% formaldehyde solution is added to improve its nutritional content and digestibility.

According to the test, 8-month-old lambs are produced and fattened with pelleted feed for 50 days. The average daily weight gain is 190 grams. For every 1 kg of weight gain, 6.4 kg of feed is consumed. The use of pellet feed to produce fat lambs is a feasible way to promote the development of aquaculture both in pastoral areas and in agricultural areas.

As a professional pellet machine manufacturer in China, RICHI also provide biomass pellet mill, turnkey biomass pellet plant apply for other materials, details as bellows:

b.Wood Chips Pellet Production Line

c.Kitchen Waste Pellet Production Line

d.Haystack Pellet Production Line

e.Organic Fertilizer Pellet Production Line

d.Alfalfa Pellet Production Line

e.Corn Stalk Pellet Production Line

f.Palm Shell Pellet Production Line

g.Waste Paper Pellet Production Line

h.Wood Shavings Pellet Production Line

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.