The abundant corn stalk raw material is a large supply of biomass pellet fuel. We will crush, dry and granulate the collected straw. According to different straws,we have different treatment methods. Comprehensive utilization of straw can effectively curb straw burning and atmospheric pollution.

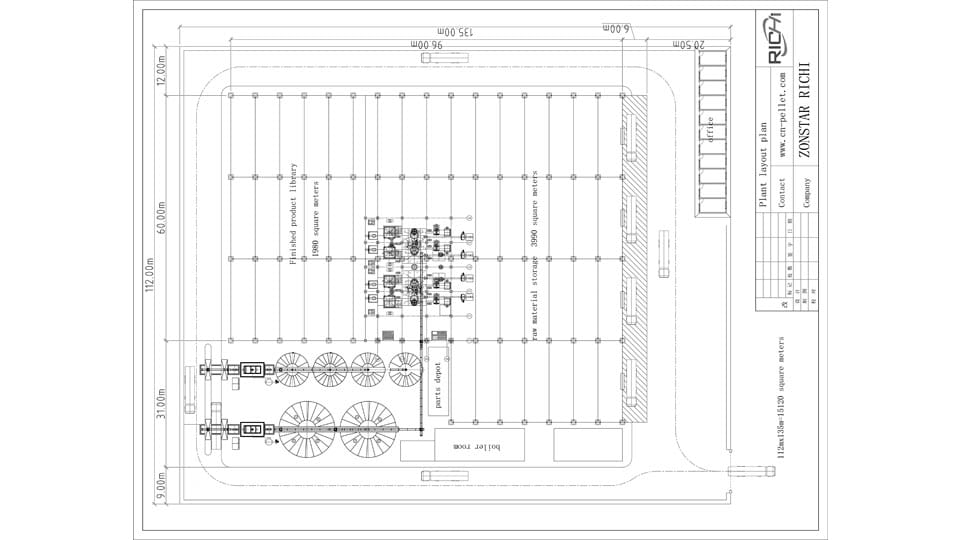

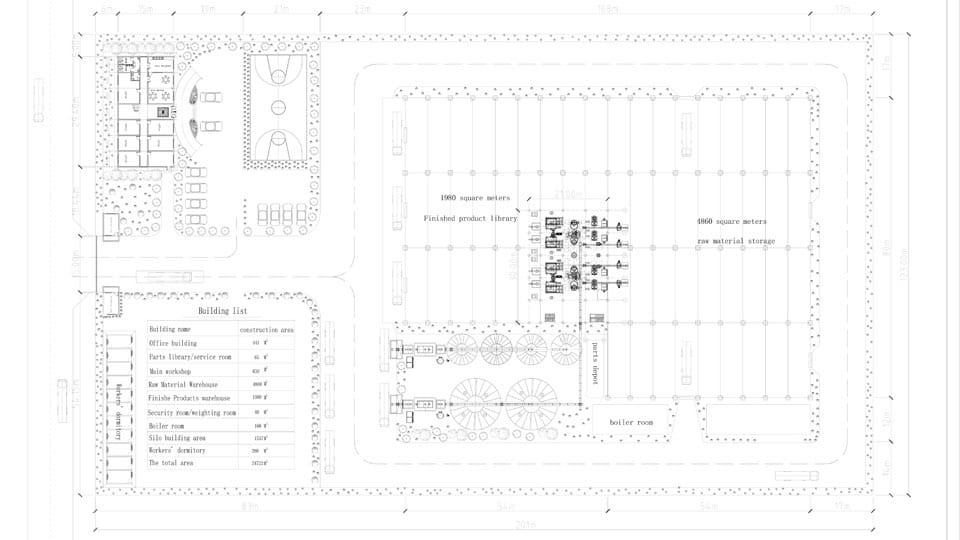

Our solutions come in a modular design so you can customize them to match your production process. At RICHI we focus on solutions that pay off, whether it's supplying the smallest spare part or serving as a long term partner. Complete Corn Stalk Pellet Production Line includes the following equipments, from the storage of raw materials to the packaging of the final pellets. Each section has professional equipment to work. Of course, according to the different needs, it may be the particularity of the raw materials or the limitations of the site. Our engineers will redesign the process, and the equipment used will be increased or decreased. Click each module below, you will see the specific equipment information.

1

Corn stalks usually has a high potential of dust, which is affected by the way of harvesting. Thus, straw needs to be screened from contaminants, such as, dust that may influence straw pellet quality and other alien materials, such as, stones, metals, and those that may damage the pellet mill in the following procedures.

2

Corn straw biomass is a tube-like or pipe-like material with a diameter of 4 to 8 mm, and wall thickness around 0.3-0.6mm. With the tube/pipe-like structure, straw can be easily processed and get the desire particle size. Generally, the grinding of straws including cutting and crushing of the straws.Because the straw is very light, this section needs a forage grinder.

3

Usually, corn stalk delivered in form of air-dried bale, with the moisture around 15%, which is the proper for straw pellet production. Therefore the drying of straw pellets is often by-passed. Even if drying is needed for straw pellet production, straw requires far less drying comparing with sawdust.

4

Straw requires special conditioning to achieve desirable hardness. Corn stalk conditioning includes the application of steam(and/or water) and the addition of binding agents or additives. Conditioning is required to achieve the necessary temperature and moisture to get the malleability and to melt the lignin to act as binding agent. Binding agents are needed to strengthen the hardness of the pellets and also to decrease abrasion during pelletizing.

This is an optional section, only a few customers who use special processes will choose. If your raw materials contain enough natural lignin to be glued together,you do not need additives and can completely ignore this section.

5

The task of this section is to make corn stalk powder into pellets .Through the pressure between ring die and rollers, to make pellets . After pelletizing , the corn stalk pellets temperature is high about 70-80 ℃ . And have 98 % qualified pellets, 2 % powder .Because the corn stalk is too light , so it is difficult to enter into the pelletizing chamber , so we add a force feeder here, to make the pelletizing process normal working .

6

7

8

9

10

11

RICHI can provide the complete turnkey project biomass wood pellet production line, from design to install . Whether you want to produce wood pellet, sawdust pellet ,rice husk pellet, EFB pellet ,grass pellet or organic fertilizer pellet, the capacity is 1-100TPH can be choose. The main machine is wood chipper,wood crusher, drum dryer, wood pellet machine , cooling machine ,rotary sereener and others . Looking forward to your consultation !

Name:The

12T/H Automatic Hemp Pellet Line

Country: America

Pellet Size:1-12mm

Main Material: Hemp

Total Power:977KW

Main Machines: Forage Hammer Mill*90KW,Hemp Mixer*1000KG/BATCH, Hemp Pellet

Machine*160KW,Cooling Machine, Crumbler Machine, Screen Machine, Automatic Packing Machine

and other equipment.

The hemp pellet mills in this project were developed for top throughput capacities in compound feed pelleting, and can process even difficult-to-press raw materials which have a high fat or fiber content. The machine sets new standards in terms of efficiency and performance: substantially lower energy consumption in comparison to conventional pellet mills, production capacities of up to 20 t/h, motor ratings of 220 or 260 kW and a customer-oriented design are just some of the advantages of this RICHI machine. However, thanks to the extremely compact design, the machine takes up very little space(workshop size:16m*7m*7.5m)– it delivers twice as much capacity with the same footprint as conventional pellet mills.

Send Inquiry

Name: 2T/H Automatic Wood

Pellet Line

Country: Canada

Pellet Size:6-12mm

Main Material: 50% moisture wood chips , 50% moisture sawdust

Total Power:385KW

Main Machines: Wood Chipper, Wood Hammer Mill Crusher, Shifter, Wood Dryer, Storage Bin,

Pellet Machine, Cooler, Auto-packing Machine and other auxiliary equipment.

In this project cooperation, exquisite process design and strong production team are very critical factors to impress customers. The final biomass pellets of the project are mainly used for export, and have high quality requirements. Environmental protection and energy saving are integrated into the design of the plan. The dust removal system runs through the entire production link, so as to achieve zero pollution and zero emissions, and meet the local regulations of customers.

Send Inquiry

Wood Pellet Plant

Wood Chips Pellet Plant

Haystack Pellet Plant

Organic Fertilizer Pellet Plant

Alfalfa Pellet Plant

Wood Shavings Pellet Plant

Hemp Pellet Plant

......

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :