Wood chips are wood that is made from forest harvesting, timber, processing and other residues and directional cultivation.Compared with directly burning wood and coal, wood pellet fuel is of high purity and does not contain other debris that does not generate heat, which will directly reduce costs for customers.

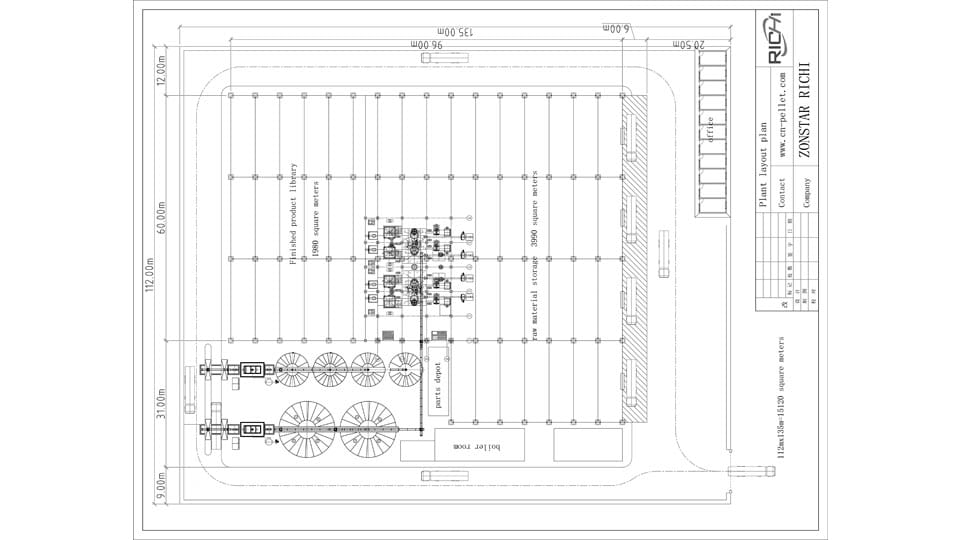

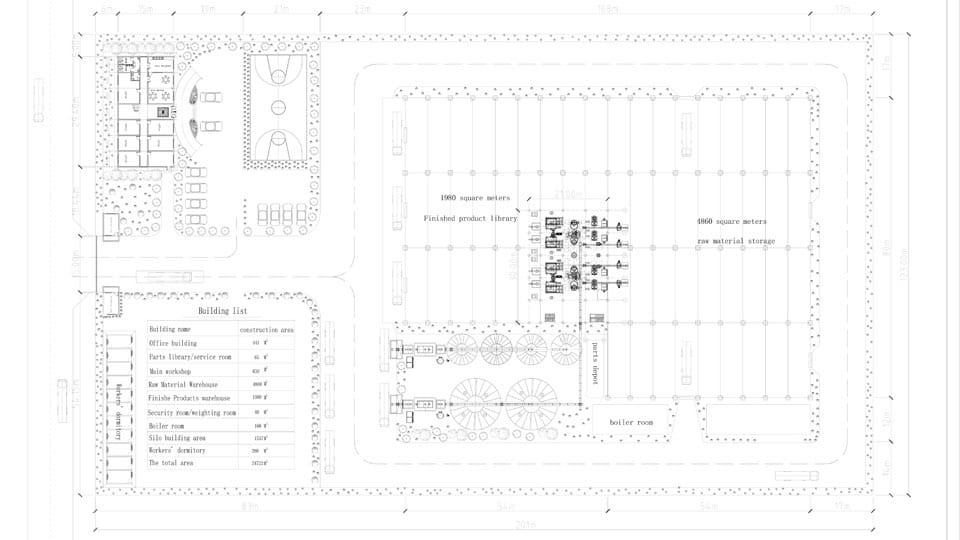

Our solutions come in a modular design so you can customize them to match your production process. At RICHI we focus on solutions that pay off, whether it's supplying the smallest spare part or serving as a long term partner. Complete Wood Chips Pellet Production Line includes the following equipments, from the storage of raw materials to the packaging of the final pellets. Each section has professional equipment to work. Of course, according to the different needs, it may be the particularity of the raw materials or the limitations of the site. Our engineers will redesign the process, and the equipment used will be increased or decreased. Click each module below, you will see the specific equipment information.

1

2

The task at this stage is to further crush the wood chip raw material into small wood sawdust.Only wood chips that meet the size requirements can be directly fed into the hammer mill, or those that have passed the chipper and coarse crushing and require further fine powder. Due to the wide range of screen sizes on the hammer mill, it can produce particles of various sizes, so it is the most common choice for wood pellet manufacturers.

3

After crushing ,materials due to the existence of air circulation inside of hammer mill and can not drop down by gravity ,so we add a draught fan and cyclone with dust collector here, to provide the strong wind for breaking the circulation , in order to the final wood sawdust drop down and also keep the environment clean.

4

For drying part, you can adjust the feeding speed, the rotating speed of the drying machine, and the inlet air temperature to adjust and to get the required moisture to make wood pellets. And the suitable moisture to make wood chip pellets is 15%-17% . ( About how to adjust, our engineer will train your labors) Different capacity, the diameter and length of the drying machine is different.

5

Whether producing single raw material pellets or mixed pellets, maintaining the consistency of raw materials is very important for pellet production plants. After the raw materials are grinded and dried, binder(vegetable oil, molasses, starch, gluten, dried lees, rapeseed cake, etc.) need to be added,so it is necessary to use a mixer machine. After mixing, the raw materials are mixed more fully and evenly, and then sent to the pellet making machine.

This is an optional section, only a few customers who use special processes will choose. If your raw materials contain enough natural lignin to be glued together,you do not need additives and can completely ignore this section.

6

7

The wood chip pellet making machine is the heart of the wood pellet production line. The pellet machine is widely used for pelletizing wood, straw and other biomass energy. The output ranges from 1 to 10 tons / hour. The biomass wood pellet machine adopts Swedish SKF bearings and Siemens motors, which can fully guarantee the wood pellet equipment capacity and stable operation.

8

9

10

The qualified wood chip pellets are packed into plastic bag from 10kg to 100kg(Now more and more biomass pellet processing plant choose tonnage scales).Then use thermoplastic sealing machine to sew, these can make the pellets dry and water-proof.To extend the wood chip pellets storage time .(The pellets should be kept from the direct sunlight, which may higher the storage temperature and increase the chance of fine percentage.The pellets should be kept in a well ventilated place because monoxide gas may be released from the wood chip pellets stored, especially in a warm environments. Be aware of the CO poisoning.)

11

RICHI can provide the complete turnkey project biomass wood pellet production line, from design to install . Whether you want to produce wood pellet, sawdust pellet ,rice husk pellet, EFB pellet ,grass pellet or organic fertilizer pellet, the capacity is 1-100TPH can be choose. The main machine is wood chipper,wood crusher, drum dryer, wood pellet machine , cooling machine ,rotary sereener and others . Looking forward to your consultation !

Name:The

12T/H Automatic Hemp Pellet Line

Country: America

Pellet Size:1-12mm

Main Material: Hemp

Total Power:977KW

Main Machines: Forage Hammer Mill*90KW,Hemp Mixer*1000KG/BATCH, Hemp Pellet

Machine*160KW,Cooling Machine, Crumbler Machine, Screen Machine, Automatic Packing Machine

and other equipment.

The hemp pellet mills in this project were developed for top throughput capacities in compound feed pelleting, and can process even difficult-to-press raw materials which have a high fat or fiber content. The machine sets new standards in terms of efficiency and performance: substantially lower energy consumption in comparison to conventional pellet mills, production capacities of up to 20 t/h, motor ratings of 220 or 260 kW and a customer-oriented design are just some of the advantages of this RICHI machine. However, thanks to the extremely compact design, the machine takes up very little space(workshop size:16m*7m*7.5m)– it delivers twice as much capacity with the same footprint as conventional pellet mills.

Send Inquiry

Name: 2T/H Automatic Wood

Pellet Line

Country: Canada

Pellet Size:6-12mm

Main Material: 50% moisture wood chips , 50% moisture sawdust

Total Power:385KW

Main Machines: Wood Chipper, Wood Hammer Mill Crusher, Shifter, Wood Dryer, Storage Bin,

Pellet Machine, Cooler, Auto-packing Machine and other auxiliary equipment.

In this project cooperation, exquisite process design and strong production team are very critical factors to impress customers. The final biomass pellets of the project are mainly used for export, and have high quality requirements. Environmental protection and energy saving are integrated into the design of the plan. The dust removal system runs through the entire production link, so as to achieve zero pollution and zero emissions, and meet the local regulations of customers.

Send Inquiry

Haystack Pellet Plant

Organic Fertilizer Pellet Plant

Alfalfa Pellet Plant

Corn Stalk Pellet Plant

Palm Shell Pellet Plant

Waste Paper Pellet Plant

Wood Shavings Pellet Plant

......

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :