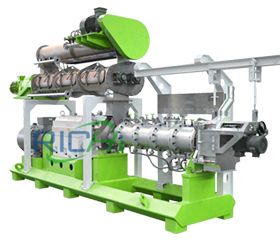

What are the unique features of your aquatic extruder machine?

The unique features of Richi Aquatic Feed Extruder are:

1. The effect of modulation and curing is lower, safer and better.

2. Multi-group linkage extrusion technology is adopted to make the activation degree better and more uniform, the nest material is smooth, and the puffing effect is better.

3. The cutting knife cross-cutting technology is adopted to ensure that the cutting material can automatically adjust the gap between the cutting knife and the template according to the output level and pressure, to ensure the flatness of the cutting material and the cutting quality, and finally realize the activity of the aquatic material Matching with forming ensures that the feeding needs of aquatic animals are met.

Aquatic feed extruder for you :

(1)Floating fish feed extruder machine,capacity : 2t/h,main power: 132kw

(2)DSP fish feed pellet extruder,capacity 3-4t/h,main power: 132kw

(3)Wet type fish fodder mill extruder,capacity : 1-1.2t/h,main power: 75kw