Using High Quality Fish Feed Pellet Mill Machine To Make Best Fish Feed For Fish Diet

1.Diverse Fish Feed Mill for Sale

Fish feed mill is specially manufactured to produce feed for fish and other aquatics. Through high pressing between die and roller, the raw material is formed into cylinders with uniform diameter and length. According to different working principle, fish feed mill is divided into two kinds, flat die fish pellet machine and ring die fish feed pellet mill.

(1)Small flat die fish feed mill

Flat die fish feed pellet mill is a fish pellet machine with lowest price, the former adopts die rotation while the latter is roller rotation. The production capacity of this flat die fish feed machine ranges from 50kg/h to 400kg/h, suitable for small scale fish feed workshop, farmed fishier, fish farming etc.But what I have to say here is that, generally speaking, we would not recommend this product to all customers who want to produce fish feed, shrimp feed and other aquatic feed pellets. The reason is simple. Customers who really understand aquatic feeds know that aquatic feeds require higher maturity and smaller particle size. If a flat die fish feed pelletizer is used, the output is very small and the pellet quality will not be very good. In addition to aquatic feed, the flat die pelletizer is suitable for small poultry feed production lines, small livestock feed production lines, small farms, etc.

(2)Ring die floating sinking fish feed pellet machine

Differ from flat die fish feed processing machine, the pelleting die of ring die type is just like a‘ring’, that is the name origin. It has two types, which are vertical type and horizontal type. Ring die fish feed pellet machine is designed in large production capacity ranging from 500kg/h to 20 t/h, more suitable for large fish feed production factory, large fishing farm etc.

①20-30t/h SZLH678 Feed Mill Equipment For Fish Feed

②25-40t/h SZLH-768 Aquatic Feed Machine For Fish Feed

③28-45t/h SZLH858 fish feed pellet making machine

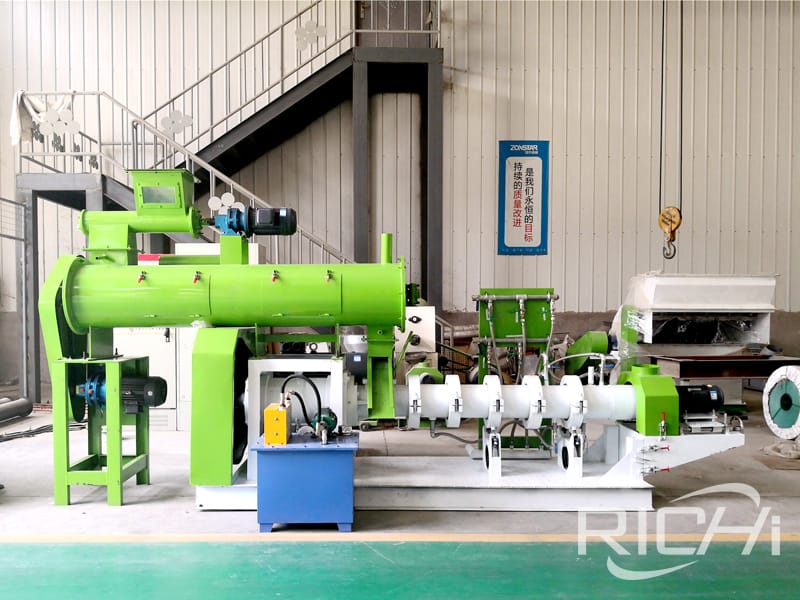

(3)Fish feed extruder machine

Besides the two kinds fish feed mills, there also has a type of fish feed maker, which is called fish feed extruder for producing floating fish feed, the production is divided into two kinds, including wet type and dry type,etc.The difference between them is the addition of steam or not,and the output.

①Floating fish feed extruder machine,capacity : 2t/h,main power: 132kw

②DSP fish feed pellet extruder,capacity 3-4t/h,main power: 132kw

③Wet type fish fodder mill extruder,capacity : 1-1.2t/h,main power: 75kw

All these fish food machine can make good quality fish diet, you can choose one of them according to your own requirement. If our single fish feed mill can not meet your requirements, we also can customize fish feed pellet processing line for you.

2.Floating fish feed production line or sinking fish feed mill plant?

Fish feedstuff is classified into two kinds, floating and sinking, which one is the best? Actually, no matter what form the fish feed belongs, only necessary nutrition is contained inside, they can help fish grow well. For fish, what nutrition most they need are protein, saccharides, fatty and vitamins and mineral elements. Generally, the type of fish decides the form of fish feed, thus the floating fish feed is suitable for weever, fish fry and invertebrate aquatics, while the sinking fish feed is suitable for shrimp, crab etc. (Another thing to note is that even if it is the same fish, there will be two forms of floating and sinking.)And different fish has different feed in-taking habits, you should choose or produce the fish feed according to the actual situation of your fish.

3.Complete aqua fish feed mill plant processing flow

Cleaning-Grinding-1st Dosing-Superfine grinding-2nd Dosing-Extrusion/Pelleting-Drying-Screening-Liquid Adding & Coating-Cooling-Packaging

(1)Before you making fish feed, you should prepare the required raw materials well, this fish feed machinery can produce various of raw materials like oil cake, rice dust, maize, wheat chaff, cotton seed etc, if needing, you can add some other nutrition agents into it.

(2)Fish feed pellet mill has a strict requirement for raw material in moisture and size, the moisture should range from 12% to 18% and the size can not over than the die hole diameter. If your raw material doesn't meet the requirements, you should equip fish feed crusher for size reduction and dryer for moisture content adjustment.

(3)For pellet extruding processing, when you place the raw materials into the fish feed pellet making machine, the die and roller will rotate under the transmission of driven shaft. Then, the raw materials would be pressed into the die hole under the great pressing. The finished product is cut into uniform length by the cutter in the discharging hole.

(4)After pelleting, the finished fish feed pellet should be cooled for better use. you can put them in a cooling place for self-cooling, and we can offer you a cooling machine for saving your cooling time and prolonging the quality period of fish feed.

Want to make high quality fish feedstuff? Using fish feed milling machine can make it came true, don't hesitate and hurry to contact Richi Machinery for more information!

[More info about fish feed]

(1)China supply complete fish feed production line with low cost

(2)United Kingdom 100-150KG/H small scale fish feed manufacturing plant

(3)Bolivia 1T/H fish feed pellet processing plant

(4)120-150KG/H fish feed extruder plant in Puerto Rico

(5)1-20 tons per hour fish feed plant

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.