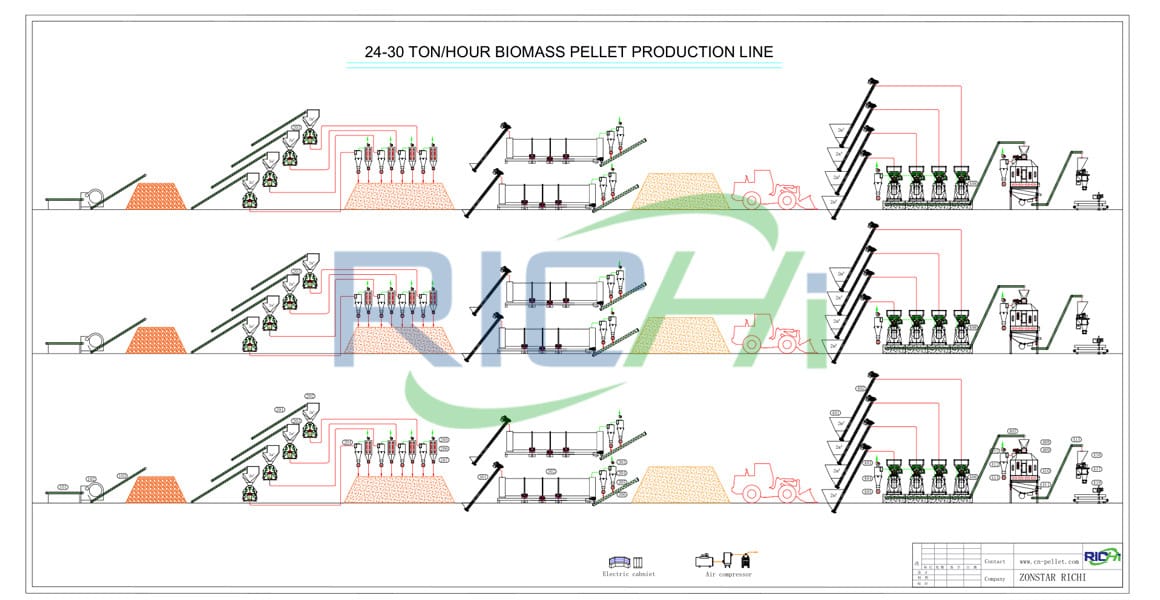

How is the whole set of the feed plant disassembled and packed into a 20 feet container?

If it is a 20 feet open-top container that is adopted, the elevator, cyclone and pipes can be dissembled and packed separately from the foundation frame while the others can be packed integrally with the foundation frame. If it is non-open-top container, further disassembling is necessary. The mixing chamber needs to be separated from the foundation frame and packed independently and then the others can be packed together with the foundation frame.

[Read More]

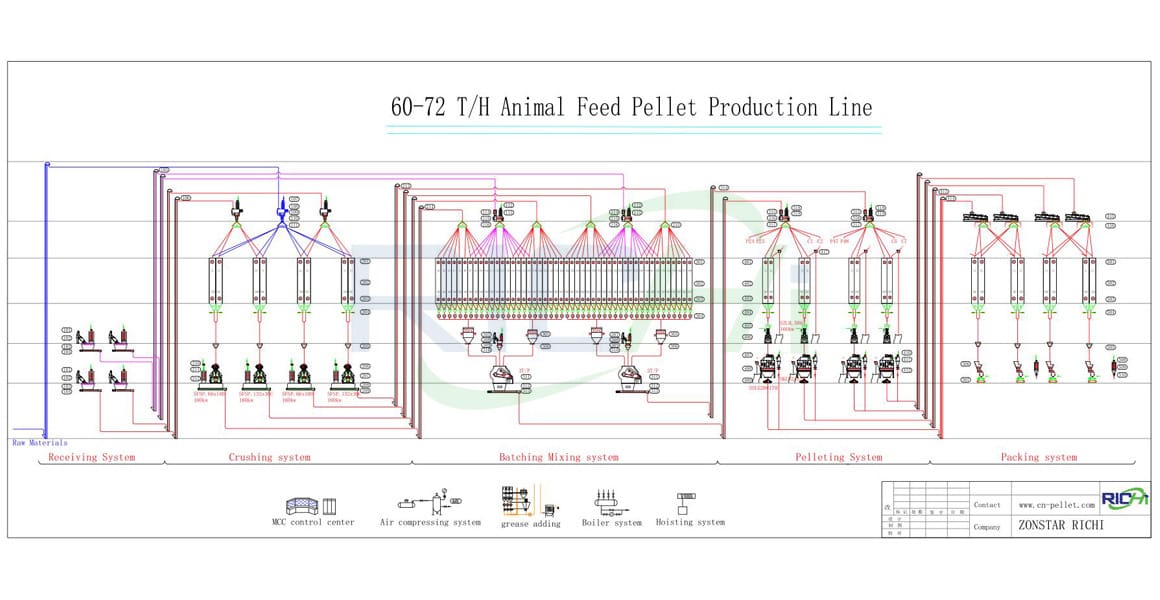

1-2TPH small scale animal feed plant

3-4T/H Animal Feed Pellet Line

5-7T/H China manufacturer poultry livestock feed plant

8-12T/H computer control feed plant for processing animal feed

13-18T/H feed manufacturing line

16-24T/H animal feed producing line

20-30T/H customized feed mill plant

30-35T/H animal feed pellet making plant

35-40T/H Animal Feed Pellet Production Plant Line

40-50T/H animal feed processing plant