What are the Service Conditions of Wet Type Fish Feed Extruder Machine?

1. Wet extruders for fish food should be installed in buildings or open shed; environment temperature is 5℃~40℃.

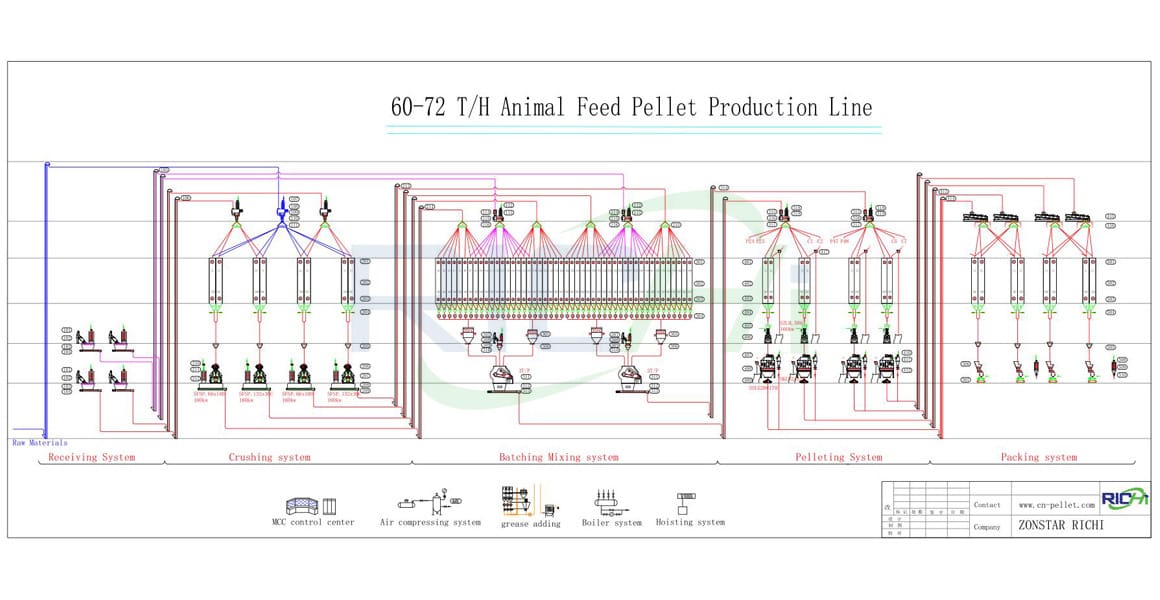

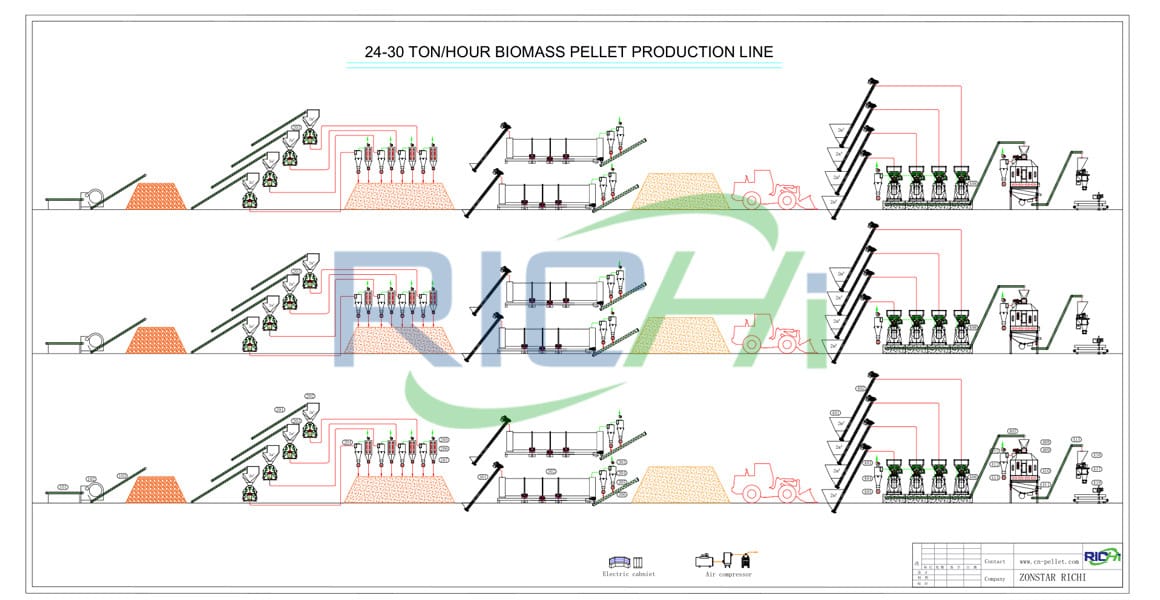

2. Process technology should match the equipments in the extruding line.

3. Working voltage should be stable and deviation is less than ± 5%.

4. Supplied steam pressure and temperature should meet the requirements of the specification.

5. The fineness of materials must meet the following standard: die hole φ2.0~φ2.5, 95% of materials over 100 mesh sieve, 100% over 80mesh sieve; die hole φ3.0~φ3.5, 95% of materials over 80 mesh sieve, 100% over 60 mesh sieve; die hole over φ3.5, 100% materials over 60 mesh sieve. Extruder cannot be boot up if it fails to meet such requirements.