3 key points of installing an wet type extruder machine

1.equipment installation

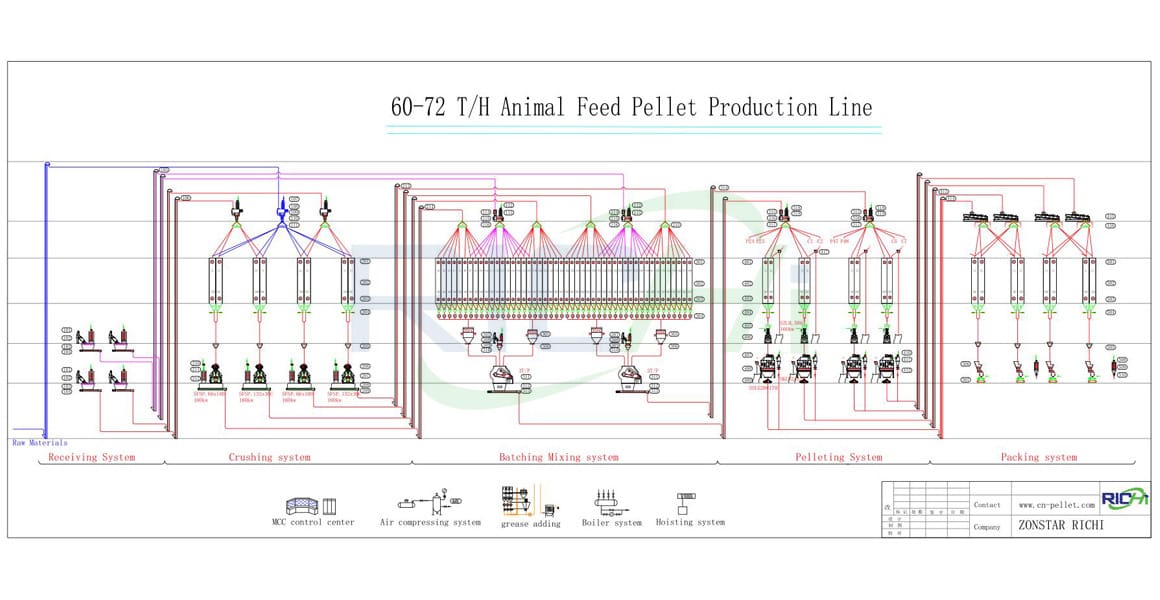

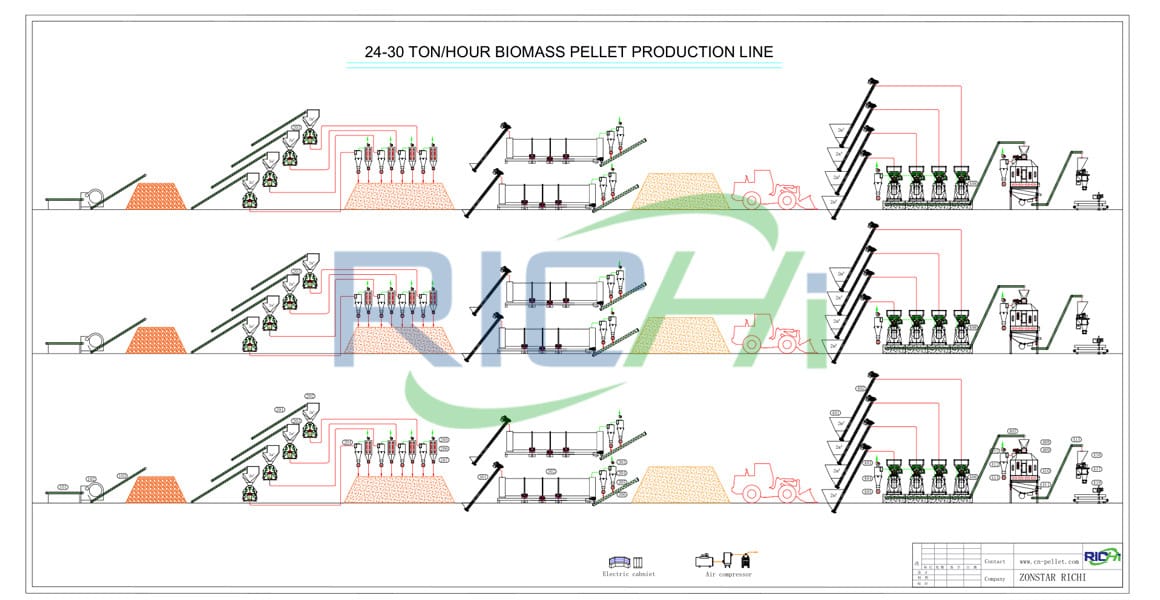

Consider the flow diagram(intake, discharge, cool), confirm floor number and relative position. And also need to take care of the space position, so as to easy operate and satisfy bearing request, ensure safety and reasonable production.

2.foundation

Equipment foundation made according to request of extruder drawing, pouring scree concrete to meet bearing request, set foot bolt to reinforce the wet fish feed extruder equipment. Weld floor steel bar with lengthen bolt, then pouring concrete if the foundation is on the floor.

3.feed hopper

Set a feed hopper on the feeder to keep production continuity. Hopper capacity keep extruder continue working more than 30min. Feed hopper has a flexible gate at its bottom, opening direction is the same as material flow direction.