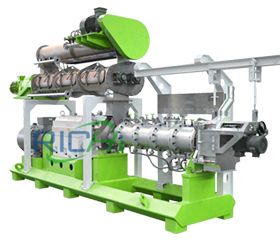

Process of wet type feed extruder machine introduction

Process of wet fish food extruder machine could be divided into three sections according to the function and position: feeding, compressing and extruding.

① Feeding section: transport and compress the tempered material, making material full fill screw chute. bolt in this section is single-start thread, which takes up10%~25% of bolt full length.

② Compressing section: double thread screw bolt, equal diameter, depth of screw chute becomes lighter along material moving direction, so making compression of material. This section is longer, taking up 50% of bolt full length.

③ Extruding section is also double thread screw bolt with equal diameter, screw chute is more lighter, extrusion force can be up to 30~100kg/ cm2, temperature is 120~170℃. Bolt and barrel of this section have the most serious abrasion because of the biggest force and highest temperature. This section takes up 15%~30% of bolt full length.

At the end of extruding section is mold, material extruded from mold holes into air. Force and temperature abrupt dropped, volume expand, moisture flashing evaporate, dehydrate and solidify, to become the extruded feed. Volume after extruding is about 9~13 times bigger than before.