How to start animal feed factory with 40 tons per hour for poultry and cattle feed?

How to start animal feed factory with 40 tons per hour for poultry and cattle feed? Today Richi Machinery will introduce to you the steps of starting high return 40t/h animal feed factory, the required procedures, process design and animal feed production equipment configuration.

Process of starting animal feed factory 40t/h

- Choose a good place to build the animal feed factory for poultry and cattle feed;

- Need to purchase animal feed processing equipment for poultry and cattle feed production;

- Need to apply for a feed processing license, the state stipulates that the production and processing of feed must have a feed processing license;

- Purchase the testing equipment required for the feed processing license to lay the foundation for the later application of the feed processing license;

- Choosing a good raw material supplier, processing feed requires processing raw materials into finished products;

- The testing equipment required to apply for a permit.

Conditions shall be met to apply license to start animal feed factory

- Have plant, feed making equipment, technology and storage facilities suitable for the production of feed and feed additives;

- Have full-time technical personnel suitable for the production of feed and feed additives;

- Have the necessary product quality inspection agencies, inspectors and inspection facilities;

- The production environment meets the safety and health requirements of the state;

- Pollution prevention and control measures are in line with national environmental protection requirements.

Complete 40 tons per hour animal feed factory plan design

Raw material for animal feed factory with 40t/h capacity

Conventional poultry and cattle feed materials include corn, wheat, barley, oats, sorghum, soybeans, soybean meal, fish meal, amino acids, miscellaneous meal, whey powder, oil, meat and bone meal, grains, feed additives and other feed materials of more than ten varieties.

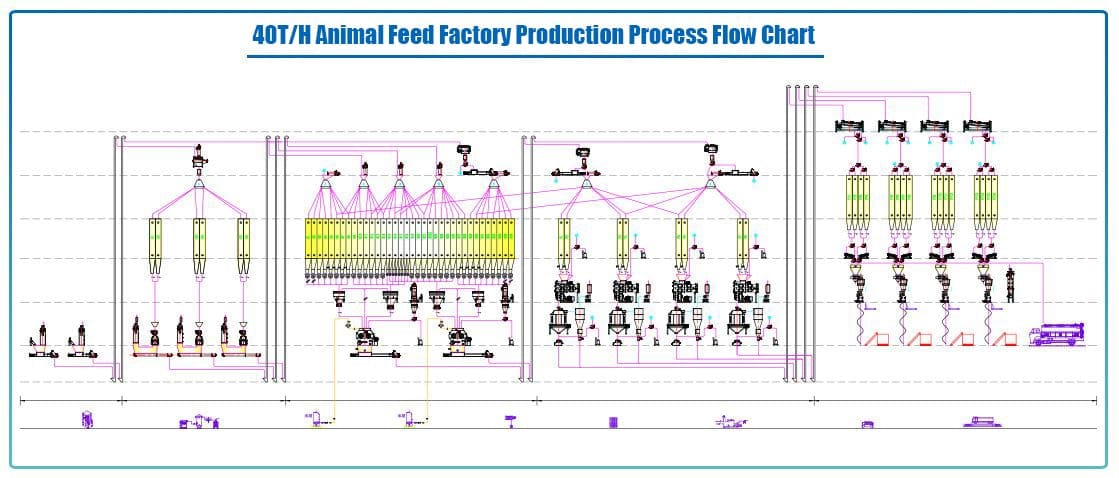

Process flow for animal feed factory with 40 tons per hour

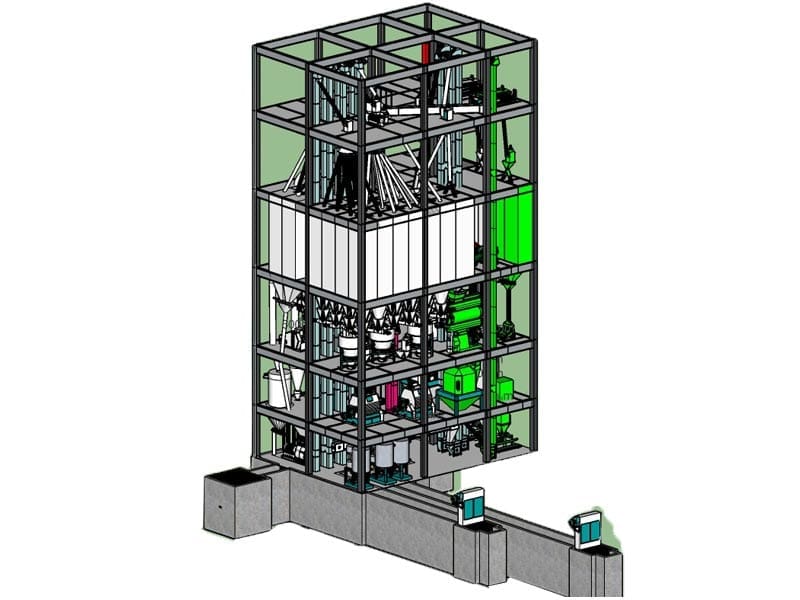

The characteristics of poultry and cattle feed are moderate crushing fineness (sieve mesh aperture 2-4mm), moderate maturation and conditioning requirements (animal feed granulators mostly use double-layer conditioners), and the finished particle diameter is large (particle diameter is about 2.5-4mm) . The four sets SZLH420 animal feed pelleting machine for animal feed factory is designed with an hourly output of 40T/H, using three crushing lines, two batching mixing lines, four granulating lines and four packing lines. The total power of the equipment is approximately: 1400KW; the construction area of the animal feed factory production area is approximately: 24.5×22.5×35m; it is equipped with a 3T boiler. The whole animal feed factory has compact design, reasonable structure, meets environmental protection requirements, and can be oriented design according to customer requirements.

- Raw material receiving and cleaning section: In this section, the pellet feeding cleaning and powder feeding cleaning in this section are separated independently, and the dust is removed separately, and the dust removal effect is good.

- Crushing section: This section adopts three animal feed hammer mill crushers, each crusher is equipped with two smashing bins, which can crush different animal feed raw materials at the same time to improve production efficiency. Before the raw materials enter the warehouse, impurities are removed by a magnetic separator to ensure the safe operation of the crusher.

- Batching mixing section: This section uses 36 batching bins, including 4 shared bins and two sets of batching mixing systems. Each batching system is equipped with two batching scales for simultaneous batching. The batching program independently developed by RICHI is controlled by RICHI's independently developed batching program to achieve precision Fast and slow feeding, fast batching speed and high precision.

- Granulation section: This section adopts four double-layer quenched and tempered animal feed pelletizer machine for poultry and cattle feed, each animal feed pelletizer machine is equipped with two silos to be granulated, and it is convenient to switch varieties to change. After granulation, it enters the pellet cooler, the animal feed crushing machine, and the elevator into the rotary grading sieve in order for screening. The finished product enters the packing bin, the powdered material is screened out and returned to granulation, and the large particle material is screened out and returned to the aniaml feed grinding machine for crushing.

- Packing section: This section has a total of 16 finished product warehouses, of which 8 warehouses are dedicated to storing finished granular materials, and 4 powder and granular materials can be stored. The powder finished product warehouse is designed with a unique anti-classification device. Granules or powders are finally automatically weighed and packaged by a packaging scale, and a bulk truck is designed for packaging and transportation.

- Auxiliary section: Dust removal system to improve the working environment of workers; grease addition system, common feed mixers to add, improve the palatability of feed.

What equipments are needed in the 40t/h automatic animal feed factory for poultry and cattle feed?

- Cleaning equipment: pellet cleaner SCY100, designed to produce 30-50T/H per hour; powder sieve SQLZ90X80X110, designed to produce 30-50T/H per hour.

- Crushing equipment (3 sets): animal feed crusher machine SFSP668*1000, 132KW, designed with an hourly output of 15-18T/H/set (¢3.0mm mesh).

- Weighing equipment: batching scale PCS20/PCS10, batching accuracy: dynamic ≤ 3‰, static ≤ 1‰.

- Mixing equipment (2 sets): horizont feed mixer SHSJ4, (30KW, 2000kg/batch), designed with an hourly output of 20-30T/H/set. Mixing uniformity CV≤5%.

- Pelleting equipment (4 sets): animal feed pelletizing machine SZLH420, 110KW, designed to produce 10-12T/H/set per hour.

- Cooling equipment (4 sets): feed pellet cooler SKLN6, designed to produce 10-15T/H/set per hour.

- Packing equipment: belt scale (both powder and granular materials), packing range 20-50kg/bag, 6-8 bags/min.

How much to start animal feed factory with 40 tons per hour for poultry and cattle feed?

Cost to start animal feed factory with 40 tons per hour for poultry and cattle feed is 450000-850000USD.

Reducing Processing Input Cost For Your 40T/H Animal Feed Factory

This may be considered as the best way for many people. When you reduce the cost of ingredients involved in animal feed factory 40 tons per hour, high profits will come up. It is better to look for other ways before lowering input costs.

(1)Increasing Animal Feed Production Rate For Your 40T/H Animal Feed Factory

In long term, you may want to save money and have to cater for damages the poultry and cattle feed making equipment involved, and yet you could have solved it earlier. Increasing the productivity of the animal feed factory processing machine would be practical and achievable way by producing more consideration tons of feed pellets in less time, which further can expanding the profitability.

(2)Ensure High Quality Feed Pellets For Your 40T/H Animal Feed Factory

To ensure the animal feed factory productivity is at its best, you need to have a great balance between production rate and feed pellet quality. Good quality poultry and cattle feed pellets represent a high return on the investment, while low quality feed pellets are certainly not going to be profitable in the long run.

(3)A Proper Energy Savings Plan For Your 40T/H Animal Feed Factory

Investing in motors that save energy can save the costs that may be brought by broken steam lines. This also has effects on the environment that the 40t/h animal feed factory is in and the people around it. The energy that is environment friendly and better for workability would be great.

(4)Good Housekeeping For Your 40T/H Animal Feed Factory

To increase productivity, it is better to have a good housekeeping program, which will ensure the animal feed factory where employees are working is clean. It should also be in the lookout for rodents and pests that may come to destroy the animal feed factory machines being involved at work.

(5)Good Data Collection For Your 40T/H Animal Feed Factory

It may seem like something that is not be considered in this case, but the truth is it is very vital. It is essential to pay attention to the quality of the ingredients being involved. Track both the inputs and outputs to have proper records, and it will show when the poultry cattle animal feed factory production is increasing or decreasing.

In this way, the profits of animal feed factory for poultry and cattle feed production may be guaranteed. If you still questions about it how to achieve the profits when starting animal feed factory for poultry and cattle feed pellet making business, please contact Richi Machinery or other professionals for guidance. We are always here for your needs!

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.