How to control cattle feed plant cost for cattle feed pellet production?

Cattel feed plant is researched and developed to produce nutritional feed for cattle animals. Due to the specialty in nutrition and feeding methods, many farmers or feeders choose to make feeds by themselves, the equipment used for making feed is called cattle pellet feed plant.

Whichever kind of animal feed you make , the production cost is the most important thing to consider, in which the cattle feed pellet making plant cost takes up a big part in the whole feed production and the poultry feed mill quality decides the final feed quality. Many people think the cost of cattle animal pellet feed production plant equals to its price, thus always choosing the cheap one for reduce the cost when they are buying the cattle feed processing plant machinery. In fact, the cost of cattle feed mill is affected by many elements, not only meaning the price.

1.What affects cattle feed plant project cost?

The first one is the feed machinery type. Our feed line for cattle is designed with various types including different working principle, output capacity, driving power etc which deciding different cattle feeding plant costs.

(1)Small manufacturing plant for cattle feed

Feed production scale comes to the second element. Feed production scale can be divided into small, medium and large scale, which is depending on your requirement and the final product application. Usually large production scale needs complete cattle feed mill plant whose cost differ to the small and medium scale production.

(2)Large cattle feed processing plant

Raw materials. Various raw materials can be used for making cattle cow feed pellets, like corn, wheat, grass, oil meals etc, colleting these raw materials can not be a problem, while raw material preparation has very strict requirement: moisture content should kept in 12%-15% and size should be within 3mm. Unsuitable raw material requires more processing procedures, thus affecting the cattle feed pellet processing line plant cost.

Actual regional situation comes to the last but not the least one. Regional economic level affects the cattle pellet making plant greatly. For example, in developed countries, with high economic developing level, high degree of modernization, they always requires high level for automation to realize continuous production; while in developing countries or regions, they quires lower than that in developed countries, which affects the cost of cattle feed pelletizing production line.

2.Cattle feed mill processing plant cost in cattle feed mill production

With the development of cattle industry, feed industry has been developed a lot as well leading the popularity of cattle feed mill production, and the cattle feed mill cost is affected as well.

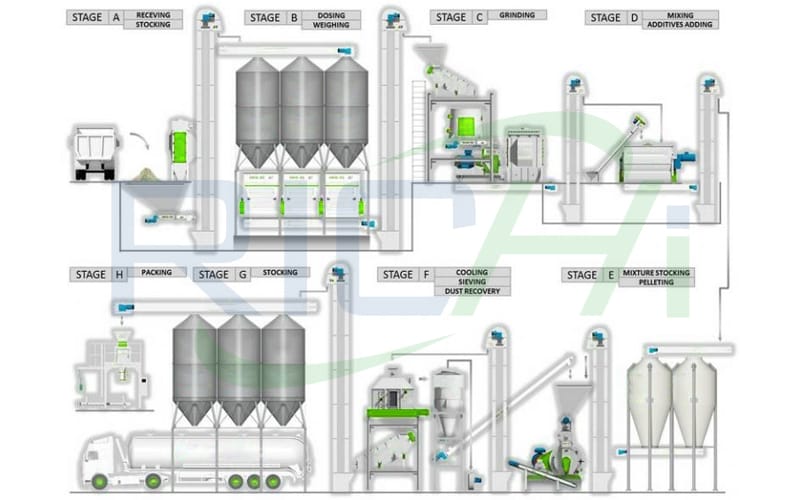

Complete feed production for better quality feed includes a series processing including, drying, mixing, pelletizing, cooling, sieving and packing deciding the needed equipments consisting of hammer mill, dryer, cattle feed milling machine, feed pellet cooler, packing machine and other conveying equipments, thus needing adequate raw materials, labors, energy consumption etc to keep continuous production. But production processing is not exactly the same in all the cattle animal feed pellet making line, we can customize the unique cattle feed pellet production plant for you based on your actual requirements and situation, meanwhile the cost of cattle feeds production line can be controlled in some extent.

3.How to control cattle feed pellet making line cost well?

According to the affected elements mentioned above, we can see that the cattle feed pellet processing line can not be reduced easily, but can be controlled in some extent.

For instance, choosing cattle food production line type. You should consider the cattle feed producing line company or manufacturer carefully in the aspects of experience, history, certification, factory strength etc, and choosing the reliable one. Reliable and experienced company can help you customize the feed production project within your requirements and actual situation, thus controlling your cost of cattle feed manufacturing line well.

Customized cattle feed mill plant from Richi Machinery:

1-2TPH small scale cattle feed plant

3-4T/H Cattle Feed Pellet Line

5-7T/H China manufacturer cattle feed plant

8-12T/H computer control feed plant for processing cattle feed

13-18T/H cattle feed manufacturing line

16-24T/H cattle feed producing line

20-30T/H customized cattle feed mill plant

30-35T/H cattle feed pellet making plant

35-40T/H Cattle Feed Pellet Production Plant Line

40-50T/H animal feed processing plant

50-60T/H manufacturing plant for cattle feed

60-72T/H large capacity cattlel feed processing line

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.