- High Crushing Efficiency

- Frequency Conversion

- Work Smoothly

- Safe and Reliable

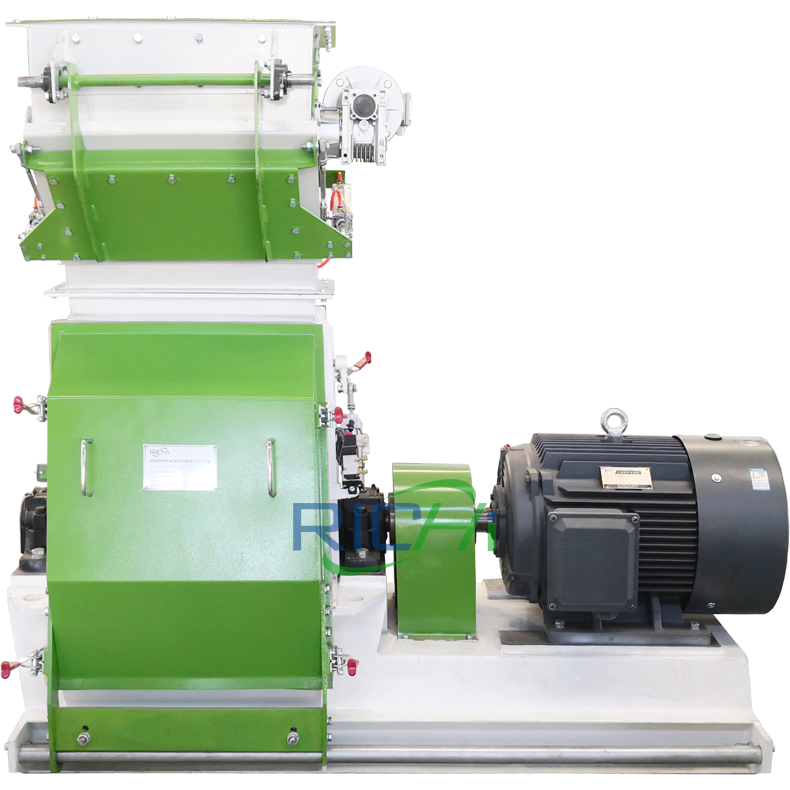

The animal feed crusher adopts hammer blade design, which can be used to crush common feed materials, such as corn, wheat or soybean, etc. Because of the high output, it is usually used for crushing operations in large farms or feed mills. It can be used alone, but it is generally installed in a feed pellet production line and used in conjunction with other feed processing machinery (feed mixing machine, feed pellet machine).

Mode:

SFSP66*80b

Capacity:

10-13TPH

Main Power:

110KW

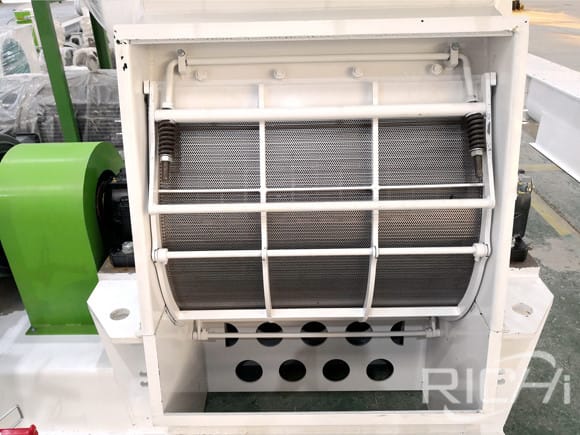

The raw materials are fed from the top of the animal feed crusher. Under the action of high-speed rotary hammer and the friction of the sieve plate, the raw materials are gradually crushed, and under the action of centrifugal force, they pass through the sieve holes and are discharged from the outlet of the feed hammer mill base.

Our equipment is processed with high-standard steel, and the thickness of the body is 20% higher than the same industry, which greatly improves the service life.

This feed crushing machine adopts two-level energy-efficient frequency conversion motor, the speed is faster, improve the grinding efficiency, shorten the grinding time.

Pneumatic gate switch is used to strictly control the feeding time to ensure the stability of production.

Built-in self-lock makes the cover flexible and safe.

Special heat-treated hammer, screen and bearing guarantee the high efficiency.

Rotor, passed the high-precision dynamic equilibrium experiment, works in slight vibration, thus has a long operating life.

The quality and know how inherent in animal feed crusher are backed by over 25 years’ experience in the pelletizing solution and other related industries around the world. The requirements for grinding a large number of special products have led to the development of feed crusher that can be adapted to almost any application, regardless of whether coarse or fine grinding is required, e.g. raw materials for the production of animal feed, fish feed, pet food, etc.

| Model | SFSP56*40a | SFSP56*40b | SFSP66*60a | SFSP66*60b | SFSP66*80a | SFSP66*80b | SFSP66*100 | SFSP138*30E | SFSP138*40E |

| Power | 30kw | 37kw | 55kw | 75kw | 90kw | 110kw | 132kw | 110/132kw | 132/160kw |

| Capacity | 3-5T/H | 4-6T/H | 5-8T/H | 6-9T/H | 8-10T/H | 10-13T/H | 12-16T/H | 15-20T/H | 18-25T/H |

| Speed | 2980r/min | 2980r/min | 2980r/min | 2980r/min | 2980r/min | 2980r/min | 2980r/min | 1440r/min | 1440r/min |

Please send your requirements, RICHI's consultants will get back to you quickly.

Please specify your requirement by referring to the following aspects,RICHI's consultants will get back to you quickly :