What is the price of 10 ton p h fish feed pellet mill line price in bd. The extruder, drier, mixer, conveyor, and other parts of the fish feed machine ?

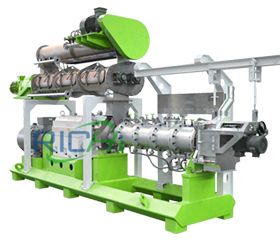

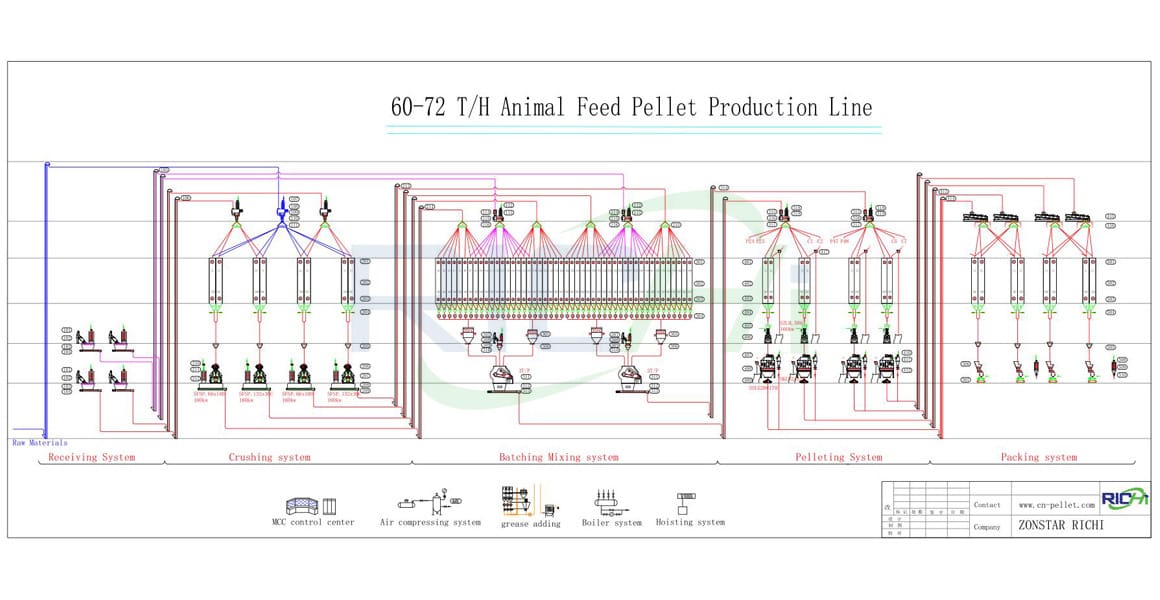

Ordinary of aquatic feed is characterized by fine grinding fineness (crusher mesh size 0.8- 2.0 mm), high curing conditioning requirements (using double jacketed conditioners), small product particle diameter (particle diameter of about 2-4.0 mm).The RICHI double SZLH420 aquatic fish feed production project was designed to produce 10-12t /H, using two micro-crushing lines, one batching mixing line, two granulating lines and two packaging lines.The total power of the equipment is about :770KW;The construction area of the production area is about 22x17.5x29m (high);allocated with 1T boiler.The dual-line SZLH420 produces 5-6t ordinary aquatic fish feed with compact engineering design, reasonable structure, meeting environmental protection requirements, and can be designed according to customer requirements.

Price of 10 ton per hour fish feed pellet production line is usually between 250000-700000USD.