How to make PSK Pellet?How to set a palm kernel shell pelletizing plant?

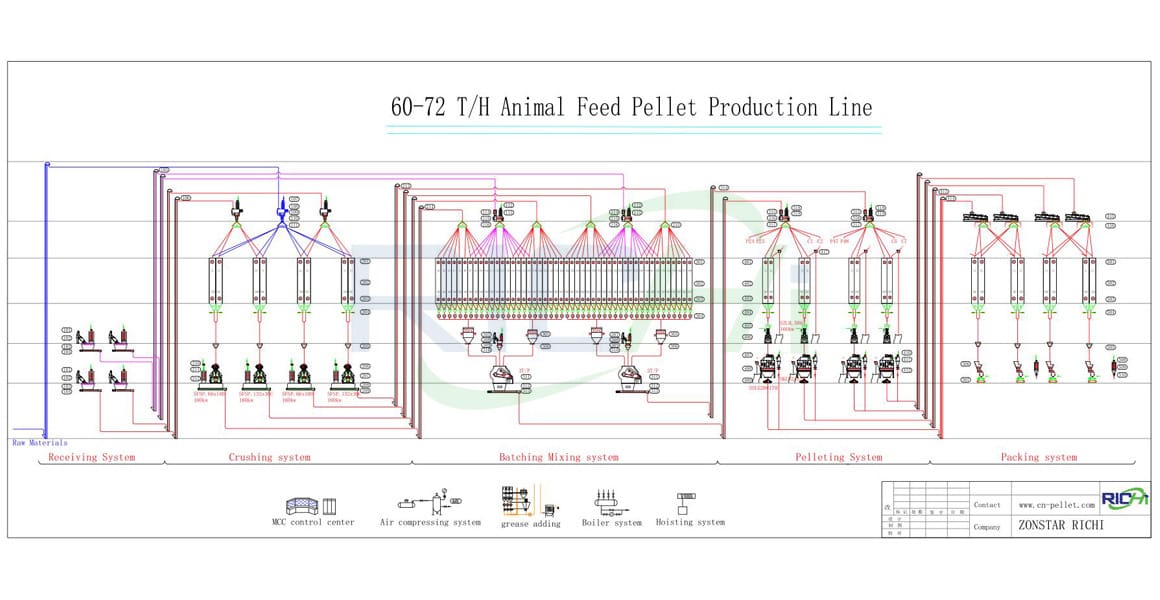

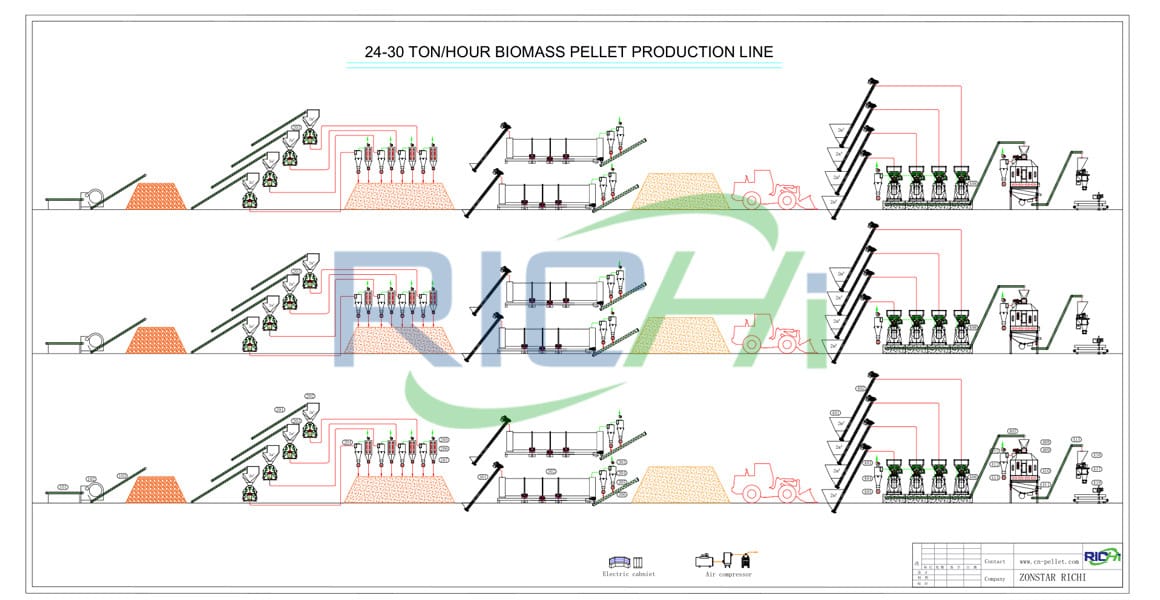

A complete palm fiber pellet production generally includes shredding, drying, grinding, pelletizing, cooling, sieving, dust recycling and packing.

Richi Machinery can offer tailor-made palm kernel shell and EFB pelletizing plant of different output. Base on years of experience on biomass pelletizing, we give some suggestions to whom plan to start a complete efb palm fiber pellet making line.

Main equioment in complete palm shell EFB pellets production process:

(1)Palm kernel shell shredder (to crush the palm kernel shell into proper size for drying)

(2)palm kernel shell dryer equipment (to get the moisture content ready for pelletizing)

(3)Palm fiber hammer mill (to grinding the materials to powder for pelletizing)

(4)Ring die EFB pellet mill (turn the power palm materials into pellets)

(5)Pellet Cooler (to cooler down the newly extruded hot pellets and hard the pellets)

(7)Electric cabinet