How many bucket sections can be added to the conveyer?

Generally, only one bucket section can be added to the conveyer, and it's better to keep total length of the conveyer no longer than 4 meters.

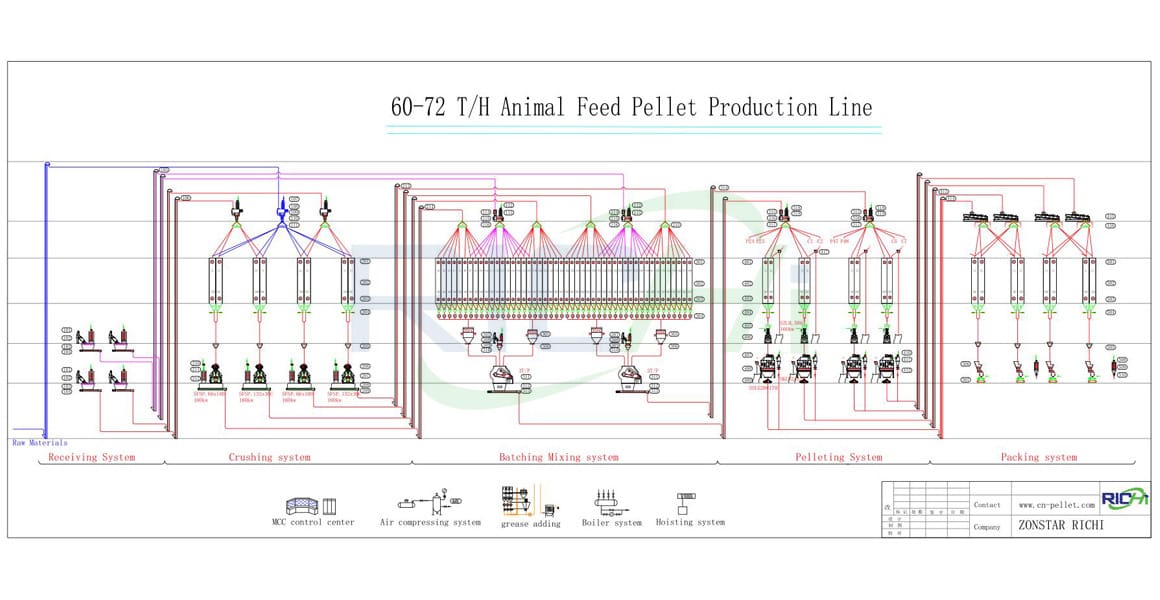

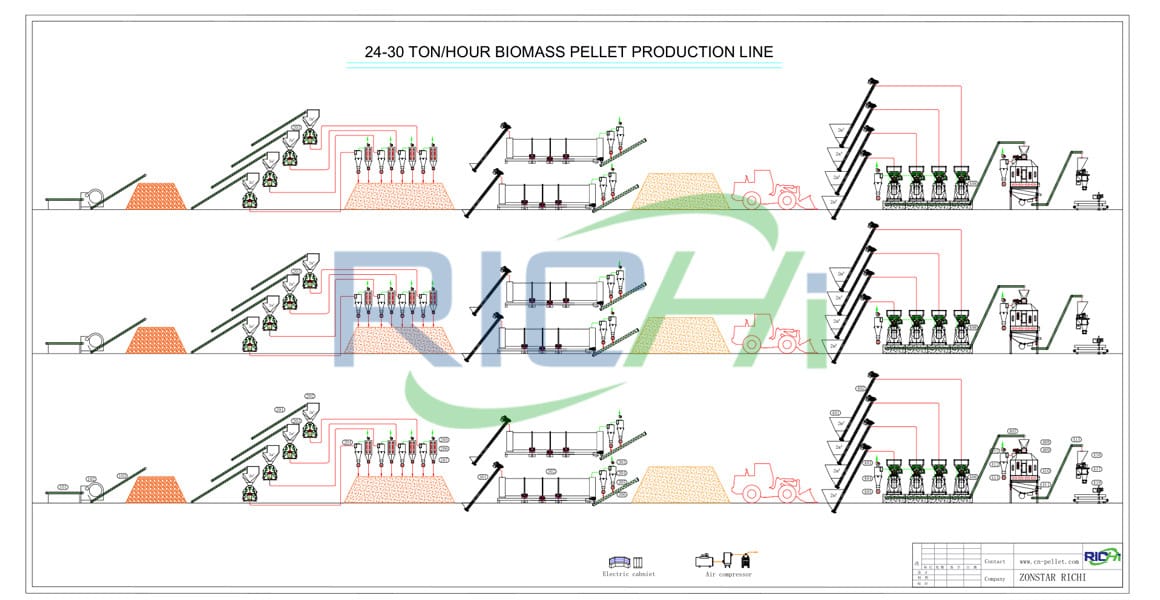

Richi Machinery is a first-class high capacity automatic animal feed pellet production line machinery supplier in China. It has built more than 1,000 feed production lines for the world. After more than 20 years of research and development, it has become a leading enterprise in China's feed machinery industry and has in-depth knowledge of every aspect of the production process. the study. Richi Machinery focuses on the overall solution of feed machinery. Before customizing the production line solution, RICHI's technical staff will understand the production process of the feed factory in detail, configure the production line according to the company's process equipment, and formulate detailed process parameters to guide the customer's production.