Some suggestions for choosing grass carp extruded feed ingredients

In grass carp extruded feed, the main feed materials used are fish meal, meat meal, soybean meal, rapeseed meal, cotton meal, DDGS, rice bran, corn gluten meal, rice protein meal, distiller's grains, brewer's yeast, flour, wheat, secondary meal, soybean oil, Vitamins, mineral salts, etc. Among them, the animal protein source undergoes deep processing and aging treatment, which leads to poor adhesion between the raw materials and has a certain effect on the tightness of the feed; and different fish pellet plant raw materials have different fiber content. When the feed is extruded, the extrusion equipment will have different effects, and the tightness of the feed will also vary greatly. Therefore, when producing grass carp extruded feed, different feed materials should be selected according to feed cost, process characteristics and feed tightness requirements. Richi Machinery summarized the following suggestions:

(1)Region and quantity of raw materials:

Combining local resources, the variety of raw materials purchased is locked within 10 types.

(2)Starch resources:

In addition to considering the nutritional value of starch resources, it is also necessary to combine its production value. There are differences in starch from different sources. Cereal starch in wheat, corn and rice has a good puffing effect. Tuber starch not only has good puffing performance, but also has very good Good bonding ability.

(3)Protein resources:

1. Select raw materials and put available amino acids first.

Soybean meal and sesame meal are burnt and cannot be used because a large amount of lysine is destroyed.

2. The selection of protein raw materials must be based on the unit price of lysine and methionine, rather than the purchase price of protein.

3. Animal protein-the core of feed quality:

a. Silkworm pupa has high fat content and is easily oxidized and deteriorated. Freshness should be checked before purchase.

b. It is best not to use meat powder in the high temperature season from August to October. Fat is most susceptible to oxidative deterioration and induces liver and bowel diseases.

c. The digestion and absorption rate of blood meal is low, and it must be puffed or spray dried to use.

d. The type of protein raw materials is also an important factor that affects the stability of feed water. Generally, fresh and high-quality raw materials have strong binding ability.

e. The combination of fish meal, blood cell meal, meat and bone meal and other animal proteins-the price becomes the main adjustment factor: the price of fish meal> 8000 yuan/ton is the node! Herbivorous fish such as grass carp and tuna bream should generally be maintained at 3% to 10%.

f. Feather powder with good hydrolysis process can enter the formula, but not more than 3%.

(4)Grease

The energy demand of fish is the first. grass carp formula should not use fish oil, soy bean oil, rapeseed oil or edible pork fat. The amount of fat in the compound feed should be kept above 4%.

(5)Premix feed

The outsourcing premixes must be analyzed and tested, and there are too many fisheye mixed beads. The preservation rate of vitamins during the puffing process has been the focus of everyone's production. The vitamins in the feed will be lost to varying degrees after undergoing puffing treatment. The premixes processed by the grass carp puffed premix production line developed by Ruiqi can coat the active ingredients of these nutrients, with strong heat resistance and storability, which is conducive to the preservation and use of puffed feed and cooperates with other nutrients to achieve The biggest breeding benefit.

Richi has professional experience in designing premix feed production lines. It is equipped with sophisticated equipment and high degree of automation. The mixer, batching bin and lifting system are made of stainless steel, and the CV value is less than 5%.

(6)Formula design:

1. Consider the expansion coefficient of the overall formula

Different feed materials have different degrees of puffing, and some raw materials, such as fish meal, have a very low puffing coefficient, and it may not be possible to puff up a large amount of fish meal in the formula. Some raw materials have higher expansion coefficients, such as corn starch. Therefore, the expansion coefficient of the overall formula should be considered in the formula design, so that the product can meet the expansion requirements.

In addition, the oil content during the puffing process also affects the puffing coefficient, plus the oil is easily oxidized at high temperatures. Therefore, for puffed feeds with relatively high oil and fat requirements, some oils and fats can only be added by spraying after puffing, but not all of them during mixing. Generally, it is ideal to control the oil and fat content to 8% or less during mixing.

2. Reasonably match plant protein and animal protein to ensure stability in water

The water absorption of plant protein raw materials is greater than that of animal proteins, and the strong absorption of raw materials will cause the increase of feed viscosity and improve the stability of water. The partial replacement of fish meal by plant protein sources is helpful to reduce the bulk density of feed and facilitate the production of grass carp floating feed. Protein is beneficial to the production of heavy feed. The bulk density of raw materials is directly related to the bulk density of feed.

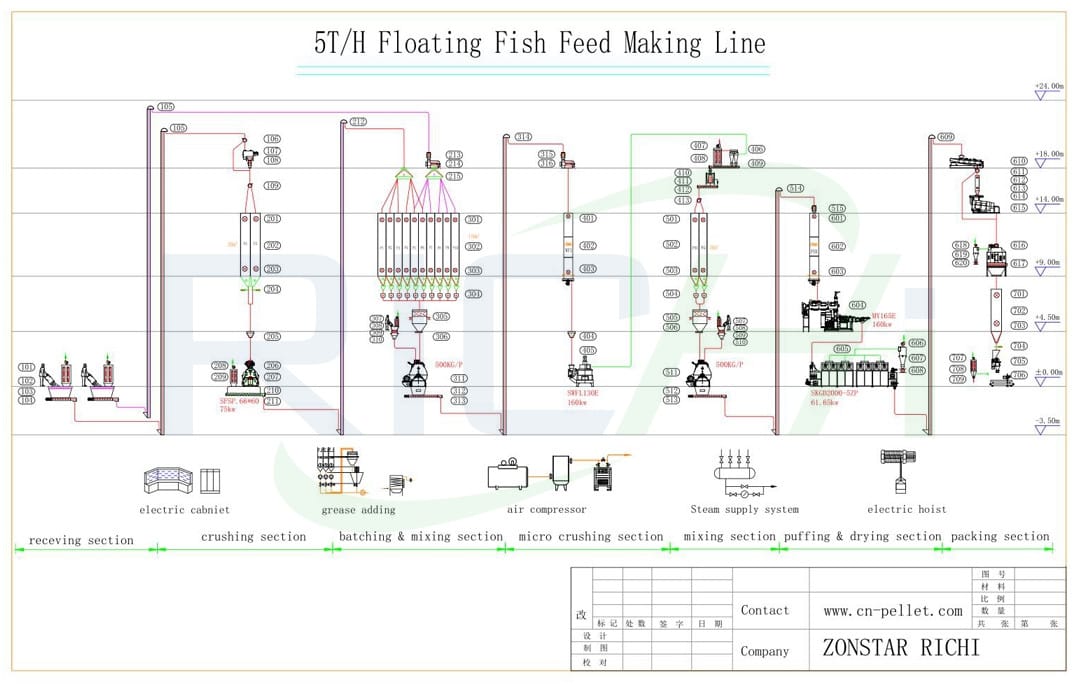

(7)Grass carp extruded feed production line process

1.Receiving the cleaning of raw materials

2.A finely pulverized material

3.A mixed feed ingredients and crushed

4.A mixed pulverized

5.Secondary and post-mix ingredients

6.Mixture sifting

7.Add water, steam conditioning, wet extrusion pelleting

8.Subsequent drying, fat spraying and cooling

9.The final grading and packaging

(8)Key equipment in grass carp aqua feed production line:

To ensure GMP cleaning is an important aspect. Different type of cleaner used for this purpose.

Raw materials need to be grinded as 225 m/microne perticle size for different type of feed.

All transportations like bucket elevator, screw & chain conveyor etc. for conveying RM & Finished goods.

Different R/M are mixed here with additives, oil/fat, medicines, etc. Good mixer ensure good quality.

Produce final pellet feed. A good pellet means "A complete feed" and a good mill can ensure that.

Extruded feeds are about 70-90° C. Cooler bring down it at normal temperature (+4° max).

7.Screening machine

To ensure supply of quality and perfect size feed, screener plays a vital role. Uneven sizes screaned-out.

Ready feed need to be packed. It can be manual or automatic bagging depends on requirement.

Want to know what fish feed production line projects have been done by Richi? Welcome to contact us for detailed consultation!

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.