Common Fault Analysis and Trouble Shooting for Wet Extruders

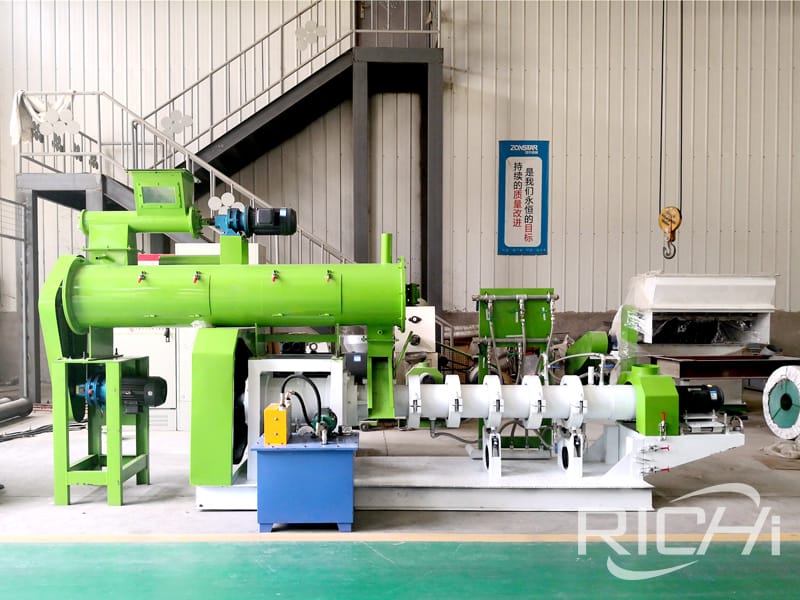

Wet fish feed pellet extruder machine product introduction:

1. Automatic control direct cooling wet fish extruder machine,specialized for production of ornamental fish, pets and aquatic extruded feed.

2. Use double thread varying pitch screw with good effect of hearing and kneading,wide range of processing pellet (1.0mm-16mm round and abnormal float feed, sinkable Feed), big extrusion pressure,quick conditioning and curing, good effect of molding.

3. In technology, use screw thread direct cooling,sliced kneading ring,inner evaporation conditioning and main shaft with variable frequency stepless adjustable speed,combining with formula to process aquatic sinkable feed and float feed.

4. Due to special structure, in the same condition,fat addition content of feed production or processing is higher than other single srew models.This model can be used some materials (as corn flour and soybean flour) dry extrusion.

Common Fault Analysis and Trouble Shooting for Wet Extruders

|

Trouble |

Cause |

Solution |

|

The powder is too rough. |

Die hole die is too large, or too larger the aperture ratio. |

Reduce the diameter of the die hole, reduce aperture ratio. |

|

The powder cannot be discharged. |

The feeding amount is too large while the water pressure and water flow is too small. |

Adjust feeding flow and make sure of the water pressure |

|

The feed is pasted. |

There is too much water. |

Adjust the flow |

|

The pellet is too large; the temperature of the extruded powder is too low. |

The screw sleeve, screw rod or die head are badly worn out. |

Replace screw rod, screw sleeve or die head |

|

No feed being discharged during normal operation. |

The discharge hole is blocked by impurities. |

Remove the impurities inside the die hole |

|

The feed has unequal sizes. |

The die hole has unequal sizes. |

Equip die hole of proper size |

|

The extruded pellet has unequal lengths. |

The cutting speed is too high or too low. |

Adjust the speed of the cutter |

|

Material splashing out of the inlet during feeding |

Too fast feeding in material or not smooth feeding or blockage happened. |

Control the feeding speed. |

|

The fracture of the powder is uneven. |

The blade has hole or the gap between the blade and die plate is too big. |

Replace the cutter, adjust the gap |

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.