Pay attention to use and maintenance of feed pellet mill in summer

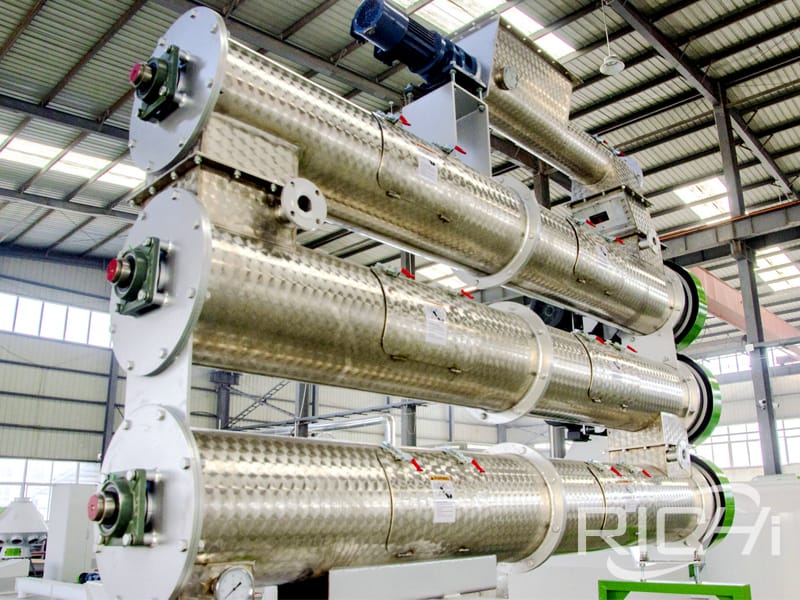

RICHI feed pellet mill series

1-2t/h SZLH250 animal feed pellet machine

3-4t/h SZLH320 animal feed pellet mill

5-7t/h SZLH350 feed pellet making machine

8-12t/h SZLH420 China Pellet Mill

10-18t/h SZLH508 china supplier poultry farming feed pellet mill

15-25t/h SZLH558 animal pellet making machine

20-30t/h SZLH678 Feed Mill Equipment For Fish Feed

25-40t/h SZLH-768 Aquatic Feed Machine For Fish Feed

28-45t/h SZLH858 fish feed pellet making machine

It has entered the summer season, the scorching sun is like a fire, giving people a sultry and unbearable feeling, people need to adjust their diet and pay attention to heatstroke and cooling.

The on-site operating environment temperature of the animal feed production plant workshop is high, and the animal feed processing pellet machine is a key equipment in the animal feed processing line. In order to ensure the stability and reliability of the pellet mill machine and other key equipment during the production process in the summer high temperature season, the operator needs to do some maintenance on the animal food pellet mill. Below, the editor will share several summer pellet mill operation and maintenance collections, which can greatly improve the life and stability of the pellet mill machine and improve production efficiency.

1.Precautions for granulation production in high temperature environment

The equipment is operated in a high-temperature environment, which is prone to the hidden trouble of abnormal failure due to the high operating temperature of the equipment. The high temperature air inside and outside the workshop is not conducive to the heat dissipation of the equipment. The high temperature of the pellet mill transmission box will also accelerate the oxidation and hydrolysis problems generated by the lubricating oil, thereby reducing the lubrication effect.

In addition, excessively high temperature will accelerate the aging of the oil seal, resulting in oil leakage, affecting the normal use of the equipment. In summer, the workshop space environment and equipment should be properly cooled. If necessary, a large cooling fan can be used to force the cooling of the pellet mill machine transmission box.

At the same time, the appearance of the pellet machine should be kept clean in summer, especially to prevent dust accumulation on the motor casing. If the management is not in place, you cannot regularly clean the device or place items on the motor and the transmission box. These will affect the heat dissipation of the device and the motor, and are likely to cause failures.

On the other hand, because the operators are prone to heat exhaustion and heat stroke for a long time, it will increase the probability of accidents when the workers in the workshop operate the equipment. In this regard, all feed making plants must have heatstroke prevention drugs and do a good job in heatstroke prevention and cooling. Workshop personnel must wear personal protective equipment in strict accordance with the requirements of the workshop and strictly implement the correct operating procedures to ensure the normal and stable operation of the granulator. To achieve the purpose of saving maintenance costs and improving the production efficiency of animal feed mill plants.

2.Routine maintenance of animal feed pellet making machine

In the summer, the replacement and addition of gear oil should be carried out according to the requirements of the product manual. The main engine recommends L-CKC220 industrial gear oil as lubricating oil. L-CKC150 industrial gear oil can be used in low temperature areas. Lithium base grease is recommended for lubricating grease.

Workshop personnel must operate in strict accordance with the equipment instruction manual. Animal feed plants strengthen training on equipment operation personnel and equipment management and inspection, and improve rules such as workshop safety production. This is also a method to extend the service life of feed equipment.

3.Requirement of raw material moisture in feed production line process in high temperature

The raw materials are stored in the warehouse in the summer. Due to the hot weather, the feed raw materials will lose moisture. In the process of feed processing, part of the raw material crushing process will also lose part of the water, reduce the raw material moisture before conditioning, the optimal conditioning moisture will not be reached and affect the conditioning effect, and ultimately reduce the degree of gelatinization and pellet forming quality.

Treatment method: The three elements of starch gelatinization are moisture, temperature and time, and the moisture content of conditioning is about 16% is the most critical element. If the average moisture of the raw material is less than 12%, the conditioning moisture will not reach 15 %. It can increase the conditioning time by increasing the conditioner configuration, while reducing the steam pressure, increasing the moisture in the steam, or spraying the cooked water directly in the conditioner to increase the moisture. The water at that time can be partially absorbed, and the aging effect is achieved.

Conclusion: The pellet mill machine is the main equipment in the production process of each feed factory, and it should be used and maintained according to the product manual. Regarding the use and maintenance of the summer granulator, what other tips and suggestions do you have during use? At the end of the article, leave a message to consult us, and we will discuss with you to maintain the stable operation of the equipment.

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.