Raw material crushing system

The main equipment used in this section is crusher. Primary crushing is aimed at coarse crushing of raw materials, which is favorable for subsequent crushing in the ultrafine crushing section and improves the productivity of the ultrafine crusher. In the primary crushing process, the raw material can be crushed to a size of 2.5-3.0 mm.

Raw material mixing system

The wide range of raw materials used for extruded feed production includes those with a high protein and fat content, so these can be easily pulverized in an ultrafine mill after they have been mixed with other raw materials.

Secondary Crushing Section

The main equipment used in this section is an ultra-fine crusher. In order to meet the requirements of the extruded feed production process, the raw materials must be ground ultra-finely so that high-quality fish feed can be produced.

Secondary Mixing Section

The main equipment used in this section is the mixer. According to the feed formula, the premix, oil and other small materials that need to be added, and the crushed raw materials can be evenly mixed to form the nutrient material.

Fish Feed Extruder

The main equipment used in this section is the twin screw fish feed extruder. The mixed material is sent to the air conditioner through a frequency-converted screw feeder, where water and steam are added to mature the material. It can produce 0.6-12.0mm feed pellets and various feed shapes.

Drying System

The main equipment used in this section is the dryer. The moisture content of extruded pellets is between 18% and 20%, and they are prone to deterioration and mold formation during long-term storage, so it is necessary to use a dryer to dry the pellets. The moisture content of dried granules is 10-11%, which allows them to be stored for a long time.

Spraying System

The main equipment used in this section is the vacuum spraying machine. Spray oil, vitamins, flavors, etc., into feed pellets to improve oil absorption and meet the energy needs of the fish. The vacuum spraying machine can improve the oil content of the feed pellets more than the ordinary spraying machine.

Cooling Machine

The main equipment used in this section is the cooling machine. The finished pellets pass through the cooling machine and are cooled to room temperature, which is convenient for storing and transporting the pellets.

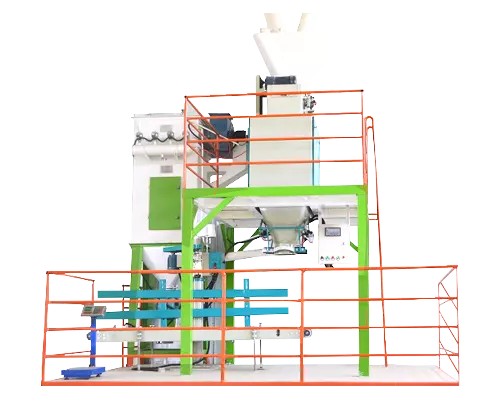

Packaging System

The main equipment used in this section is a packaging machine. With the help of packaging equipment, pellets can be packaged into pre-packaged feeds of 10-50 kg per bag. It can be equipped with a fully automatic packaging system according to requirements.