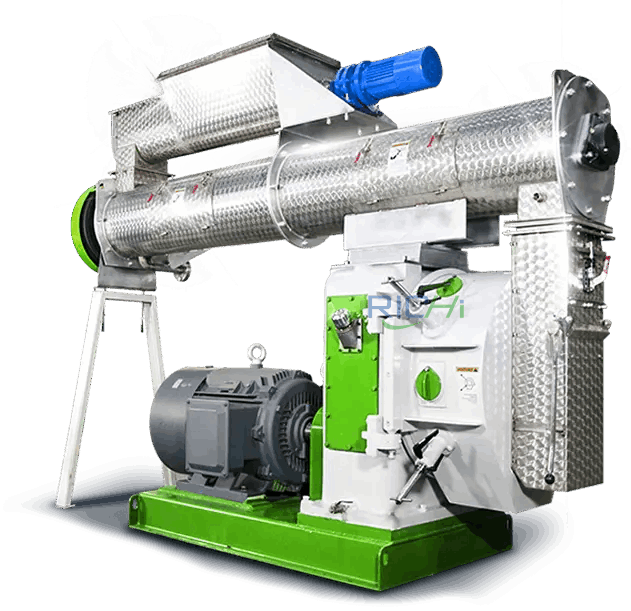

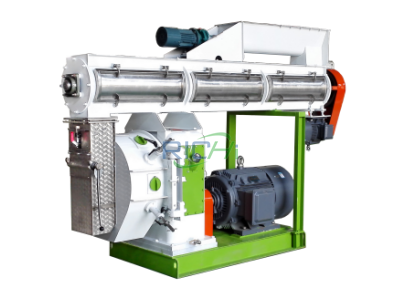

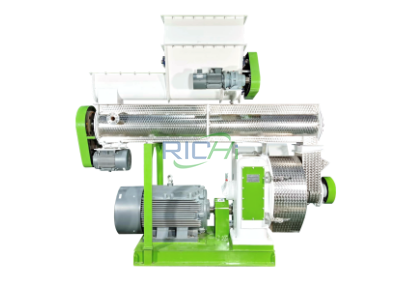

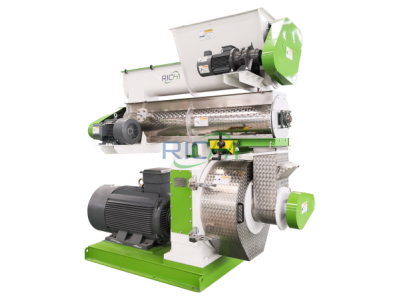

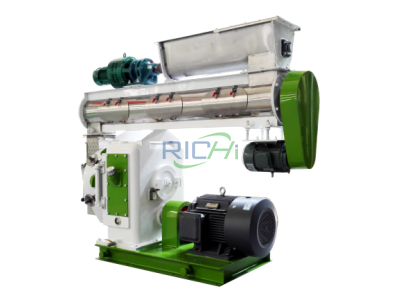

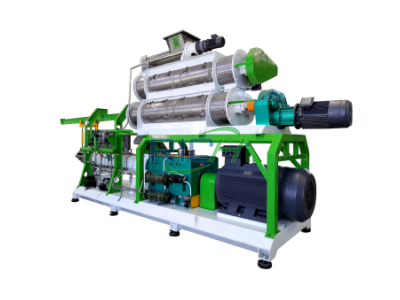

As a top feed pellet machine manufacturer, RICHI machines efficiently pelletize feed, ensuring peak pelleting efficiency at the lowest cost per ton.

RICHI MACHINERY__

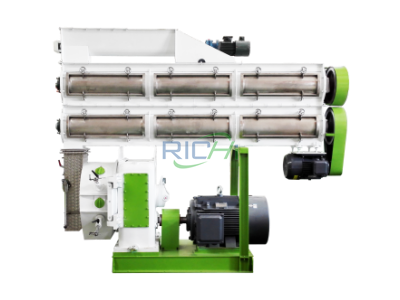

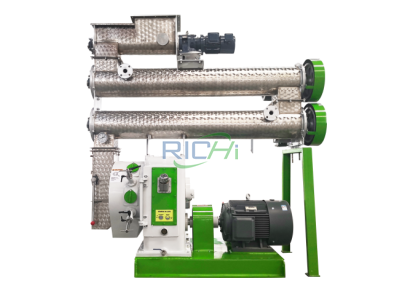

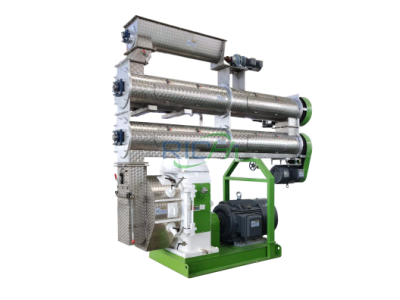

RICHI offers a wide range of poultry feed pellet machine, livestock feed pellet machine, ruminant feed pellet machine and pet food machines constructed with high-grade components that surpass industry standards. The simple, robust feed pellet machine designs have been continually improved to meet modern industry's demands for cost-effective quality and efficiency. Our feed pellet machine product offering includes:

Our range of ring die poultry feed pellet making machines provide unbeatable pelleting performance across a wide range of applications.

High-quality cattle pellet machine technology can not only extend life of your equipment, but also improve throughput and increase overall revenue.

Incorporate our engineering expertise into any and all of your pig feed pelleting systems, no matter the size, up to and including systems for total pig feed plant.

RICHI has the capabilities and sheep feed mill equipment knowledge to create the best solution for you and your process by reviewing entire process and machine setup.

Duck feed machine operating parameters, production process, and customer goals all go into providing our customers with the ideal duck feed plant solutions.

We offer horse feed pellet mill equipment tailored to your needs and manufactured to help you find increased productivity for horse feed mill production.

Using our knowledge as an Feed Pellet Machine Manufacturer, we ensure that the supplied product is correct for your application——rabbit feed production line.

You are in safe hands with RICHI MACHINERY. We know ruminant feed pellet making machines – how they are engineered and how they operate.

In order to help your pelleting system maximise its operational performance, we design livestock pellet mill that are tailored specifically with your needs and goals in mind.

You ultimately benefit from our pelleting process knowhow and can be reassured that the correct feed pellet machine is specified for your valuable feed plant.

Our wide range of chicken feed pelleting solutions allow us to service a variety of customer needs. More than 30 years of experience in feed processing guides our decisions.

Our pet food extruder machines are tailored specifically to your pet feed mill needs and goals, ensuring you get maximum value and longer wear life.

RICHI MACHINERY__

To define the most suitable feed pellet equipment for each application, RICHI Machinery makes a detailed analysis of the feed pellet production process needs, such as material characteristics and installation layout. Whether you need to grind, condition, pellet, or cool, we can meet the demands of almost every conceivable application. Your entire feed manufacturing process is covered from start to finish, and our rock-solid animal feed processing equipment lets you operate your feed mill plant at the lowest possible cost. Our feed pellet machines and whole set animal feed mill machines can handle anything you throw at them, so you can meet the demands of your customers the most cost-effective way.

Livestock feed pellet production lines and processing machines are gaining prominence owing to an increased consumption of animal based food.

We offer poultry feed production line solutions and consulting to transform a wide range of feed ingredients to safe, healthy and nutritious poultry feed.

Experience the efficiency of ruminant feed machines that minimizes downtime and maximizes output, empowering you to meet production demands consistently.

RICHI has experience in poultry premix, cattle premix feed, aqua premix feed, etc., providing premix feed plant solutions to this high-tech industry.

RICHI is a single point mash fed plant solution provider for all types of mash feed production plants including laying hen, chicken, cattle and others.

RICHI MACHINERY__

We offer different models and capacities of feed pellet making machines for different feed processing scales. We offer support throughout the lifetime of your RICHI pellet machine. Working together with you, we help maximise the benefits of your press supplying spare parts, die and roller assembly, on-site maintenance and on-going technical support.

| Model | Output (t/h) | Main motor power (kw) |

|---|---|---|

| SZLH250 | 1~2 | 22 |

| SZLH320 | 3~4 | 37 |

| SZLH350 | 5~7 | 55 |

| SZLH420 | 8~12 | 110 |

| SZLH508 | 10~18 | 160 |

| SZLH558 | 15~25 | 180/200 |

| SZLH678 | 20~30 | 220/250 |

| SZLH768 | 25~40 | 250/280 |

| SZLH858 | 28~45 | 315/355 |

RICHI MACHINERY__

From the morning eggs to the dinner-time steak, you're helping feed the animals that feed the world. That's why you can't compromise with animal feed making equipment and automation that are second best. We've perfected the design of our feed technology and equipment so that it provides a comprehensive animal feed production line solution based on your unique ingredients and production requirements.

Having the right mix of reliable, high-quality pellet machine and feed mill systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Let RICHI's advanced animal feed processing solutions transform your operations. Contact us today to learn how we can help you enhance efficiency and sustainability in your energy production.

If a customer requires animal feed plant solutions that span different departments, RICHI is adept at connecting the dots to provide a complete, multi-faceted solution to meet their needs.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Our line of processing equipment from pelleting, extruding, crushing, mixing, drying, cooling, screening, cleaning, grading, cooling, spraying, conveying and storage, combined with an in-depth understanding of your feed production business, delivers maximized growth and value.

For nearly 30 years, RICHI Machinery has had the opportunity to work with a variety of industries – learning the complexities of diverse materials, navigating unique industry challenges, and discovering innovative pellet plant solutions along the way. Whether you work with feed, biomass, wood, organic fertilizer or cat litter products, RICHI is committed to being your partner in innovation, success, and operational excellence.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

Founded in 1995, RICHI Machinery began as a pellet machine manufacturer and pellet plant system provider that steadily grew into the comprehensive service and equipment provider it is today. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI to take your operation to the next level of success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

We're here to answer any questions you may have and help you realize the future.

Our feed pellet making machine price is generally between 7,000-100,000 USD. Different models, different outputs, different prices. Support various customization requirements (some customized manufacturing will increase the cost of equipment, while others will have little impact on the price).

The raw material can be used to make animal feed pellets by feed pellet mill has corn/maize, alfalfa, wheat bran, grass, rice, beans, oil cake, etc. Usually, large size raw materials should be pulverized by hammer mill. Protein or other nutrients can also be added to the raw powder.

Feed pellet mill machine is widely used in large, medium and small aquaculture farm, grain feed mills, animal farms, poultry farms, individual farmers and small and medium-sized farms, farmers for large, medium, small feed mills use.

Our feed pellet mill has gained ISO9001-2000 Certification, CE Certification, SGS Certification patent etc. Products cover the poultry feed, livestock feed, aqua feed, ruminant feed, pet food, grass feed and straw feed and other fields. There are five main series: ring die pellet machine, fish feed pellet machine, feed pellelt extruder, straw/grass pellet machine.

(1) 40% deposit of the total amount to be paid by T / T in 7 working days after signing the

sales

contract, the balance of 60% will be paid before the goods leave the factory.

(2) 40%

deposit of the total amount to be paid by T / T in 7 working days after signing the sales

contract, the balance of 60% can be paid by L / C before the factory leave goods.

(3)

We

can negotiate specific payment terms with our client.

For standard feed pellet machines, that would be 10-30 working days; For non-standard machines and customized machines according to customers' specific requirements, it would be about 30 working days . If you purchase a complete feed production line, it will take 30-90 days to deliver.

We work with the biggest freight forwarder in China. if you need to appoint other freight measures, we can arrange them because we have rich experience and sufficient funds to handle.

Generally speaking, the minimum output feed pellet machine we can provide is 1 ton/hr, which is a ring die pellet machine. If you want to process feed types such as grass and straw, the minimum output needs to be above 500kg/hr. If you have any questions, please contact us directly for detailed product information and quotation.

Low cost, convenient operation and maintenance;

High yield, energy-saving and

environmental

friendly;

Designed by RICHI research and development team;

Nearly 30 years

experience

in feed pellet mill manufacturing, installation and commissioning;

Exported to more

than

140 countries around the world, including United States, Russia, UK, Indonesia, Netherlands,

Germany, Ghana, Senegal, Nigeria, Thailand, India, Australia, South Africa, Pakistan,

Kuwait,

Japan, Philippines, Portugal, etc.

If you need further information, please contact us

RICHI was the most outstanding team to work with. They went out of their way to make sure we had everything we needed for our feed pellet production line. During construction, a few items outside of RICHI's scope came up that would really enhance our new line. Not only did RICHI bring them to our attention, but they also took care of them for us.

Ryan Roderick

Project Manager——From Texas, USA

Get in touch with our team about your next project! We are eager to share our 30 years of industry expertise with you to take your pellet mill or pellet plant to the next level of efficiency, safety, and quality.