5-6T/H Cat Litter Pellet Machine

Project Case Video

The market demand of cat litter industry in UK is increasing year by year, and the development of cat litter pellet machinery engineering requires more and more high. Check the production video of cat litter pellet plant, to learn more the knowleadge of the UK project case. Welcome to visit our factory and equipment.

RAW MATERIAL TO FINAL PELLET

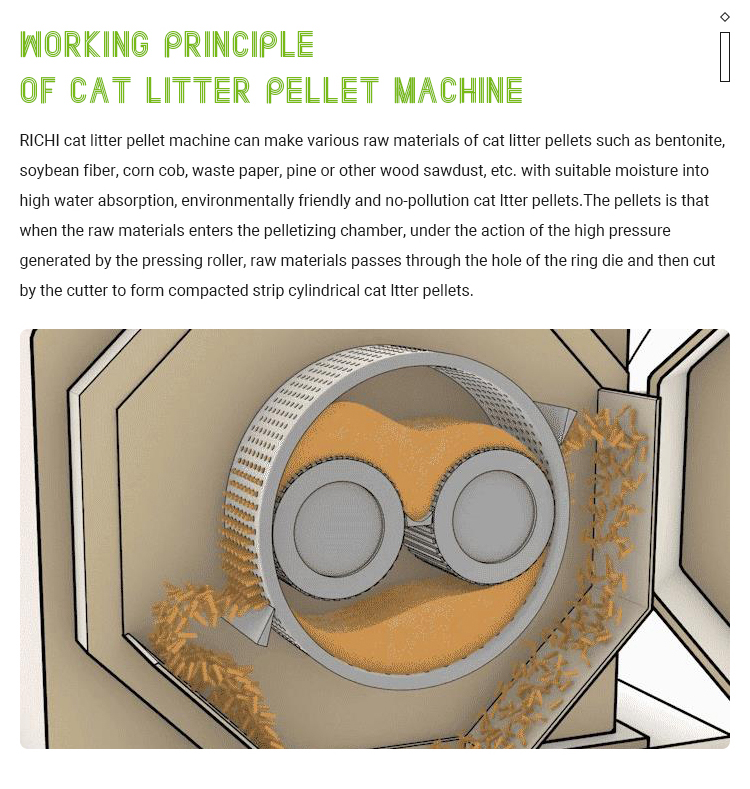

RICHI cat litter pellet machine can make various raw materials such as bentonite, soybean fiber, corn cob, waste paper, pine and others. The size is 2-12mm or other customized sizes you need.

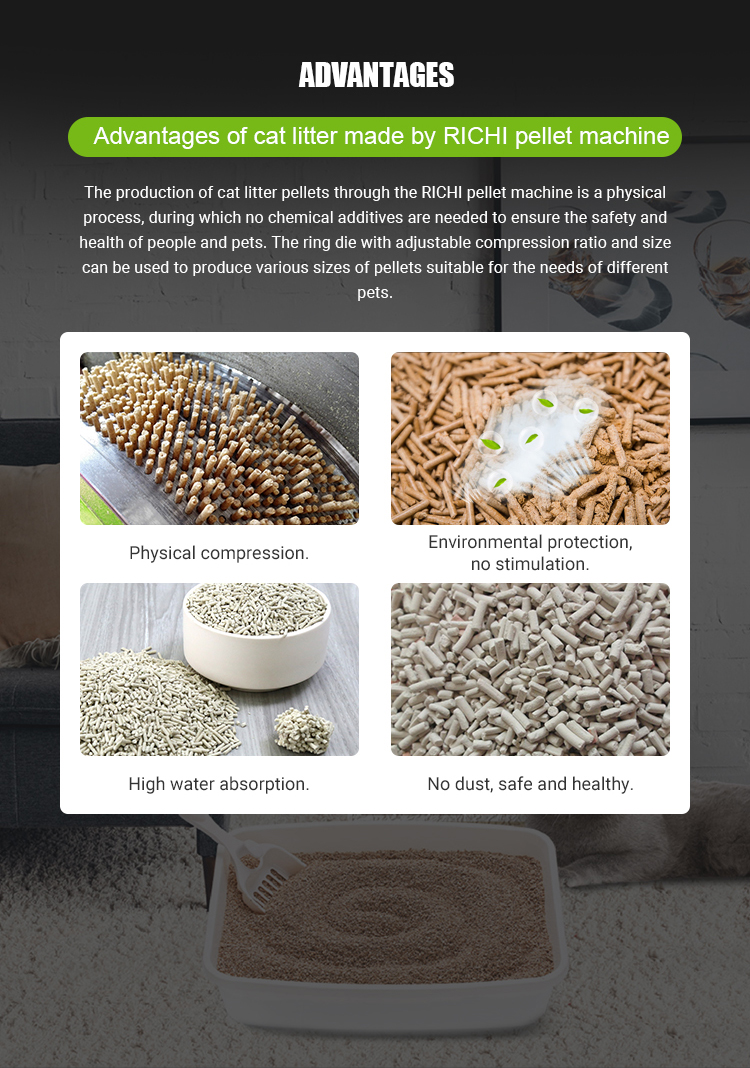

The Advantages About Cat Litter Pellet By RICHI Pellet Machine:

The production of cat litter pellets through the RICHI pellet machine is a physical process,during which no chemical additives are needed to ensure the safety and health of people and pets.

The ring die with adjustable compression ratio and size can be used to produce various sizes of pellets suitable for the needs of differents pets.

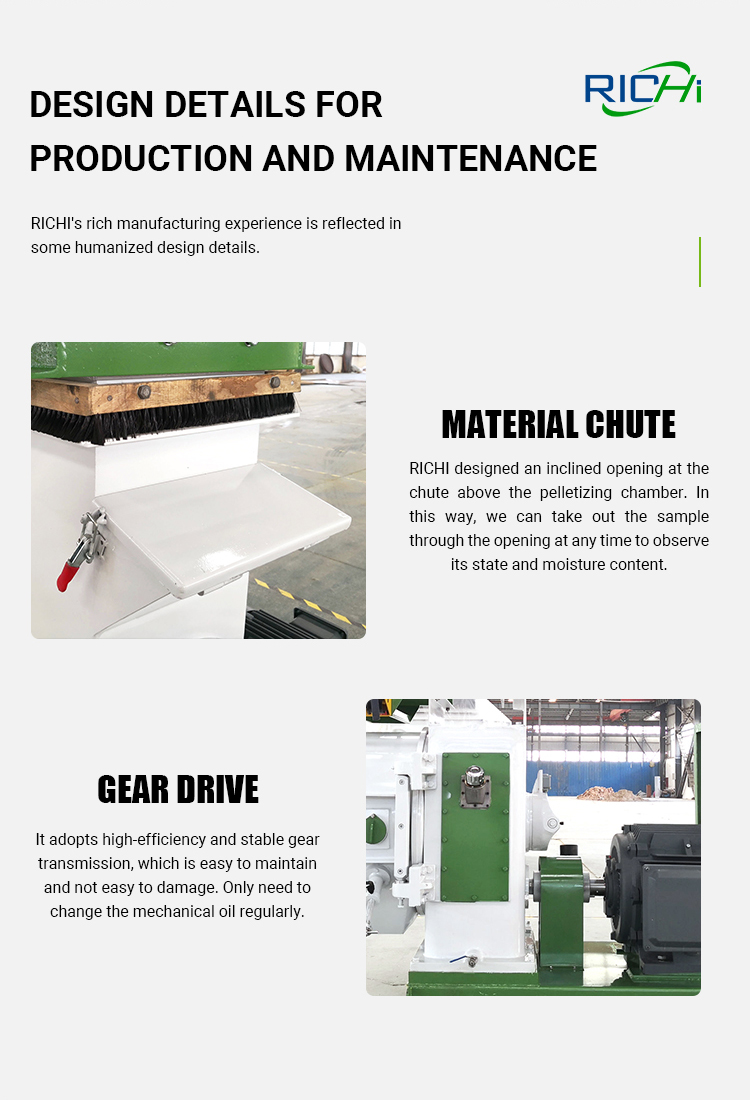

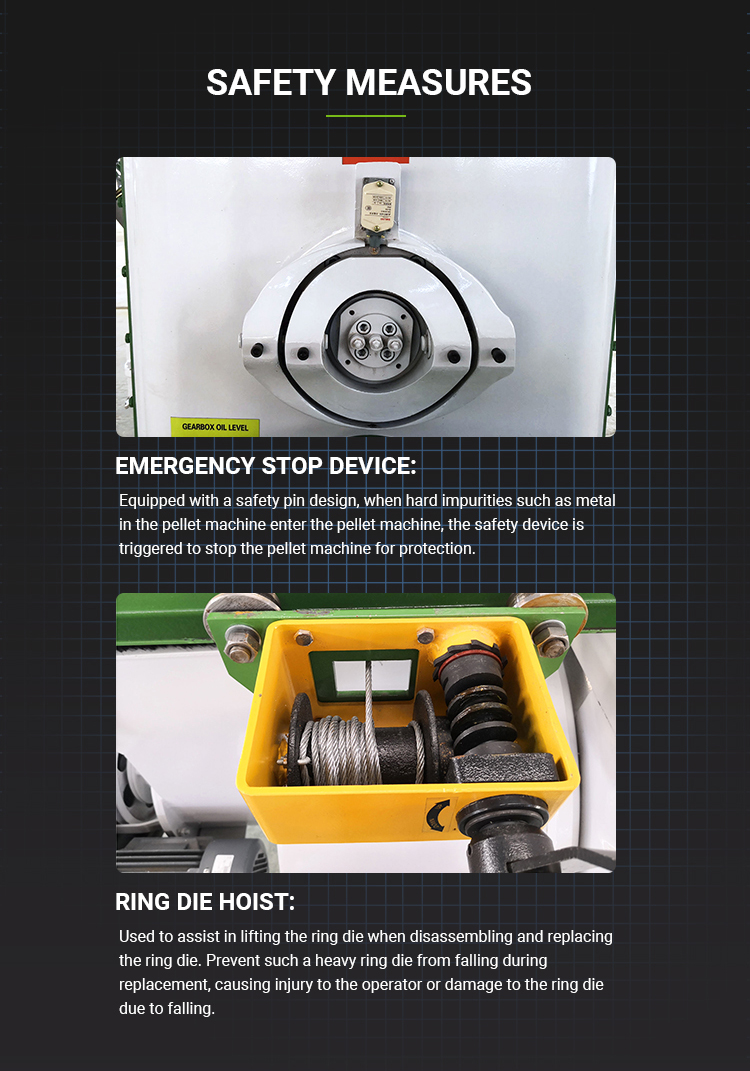

The Detail Of Cat Litter Pellet Machine

This machine include the SKF bearing, anti-cake device, frequency feeder, siemens motor, grar box, pelletizing chamber, forced feeder, material inspection port, stainless steel ring die and others.

Noe to learn more the more details about richi cat litter pellet machine.

The Quality Assurance of RICHI Cat Litter Pellet Machine

High-quality equipment is RICHI's unremitting pursuit. About richi cat litter pellet machine, you can see our pelletizing chamber and stailess steel ring die.

The pelletizing chamber is equipped with a cutter adjusting handle, which can easily adjust the distance between the cutter and the ding die, thereby controlling the lenght of the pellets.

The ring die of feed pellet machine used the 40CrMnTi, the carburizing heat treatment can improve abrasive resistance of ring die, the stainless steel doesn't corrode easily.

The Details About RICHI 5-6T/H Cat Litter Pellet Machine

In this project, our engineer provides a lot of drawing for our Algeria customers, such as animal feed complete engineering solutions, including total planning, factory layout, equipment layout, civil engineering, steel construction,install drawings, working drawing, wire and cable list, steel list, storage system, feed processing machinery, intelligent packing, and electrical control system, equipment manual.

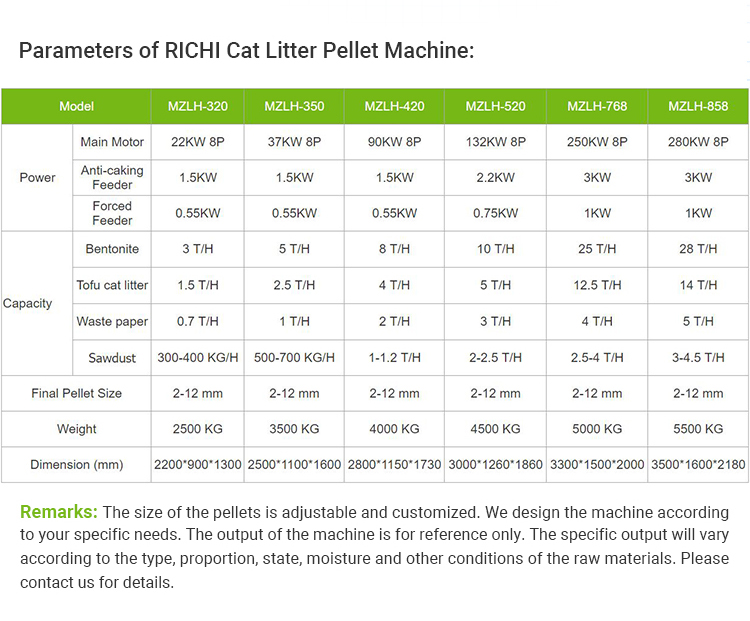

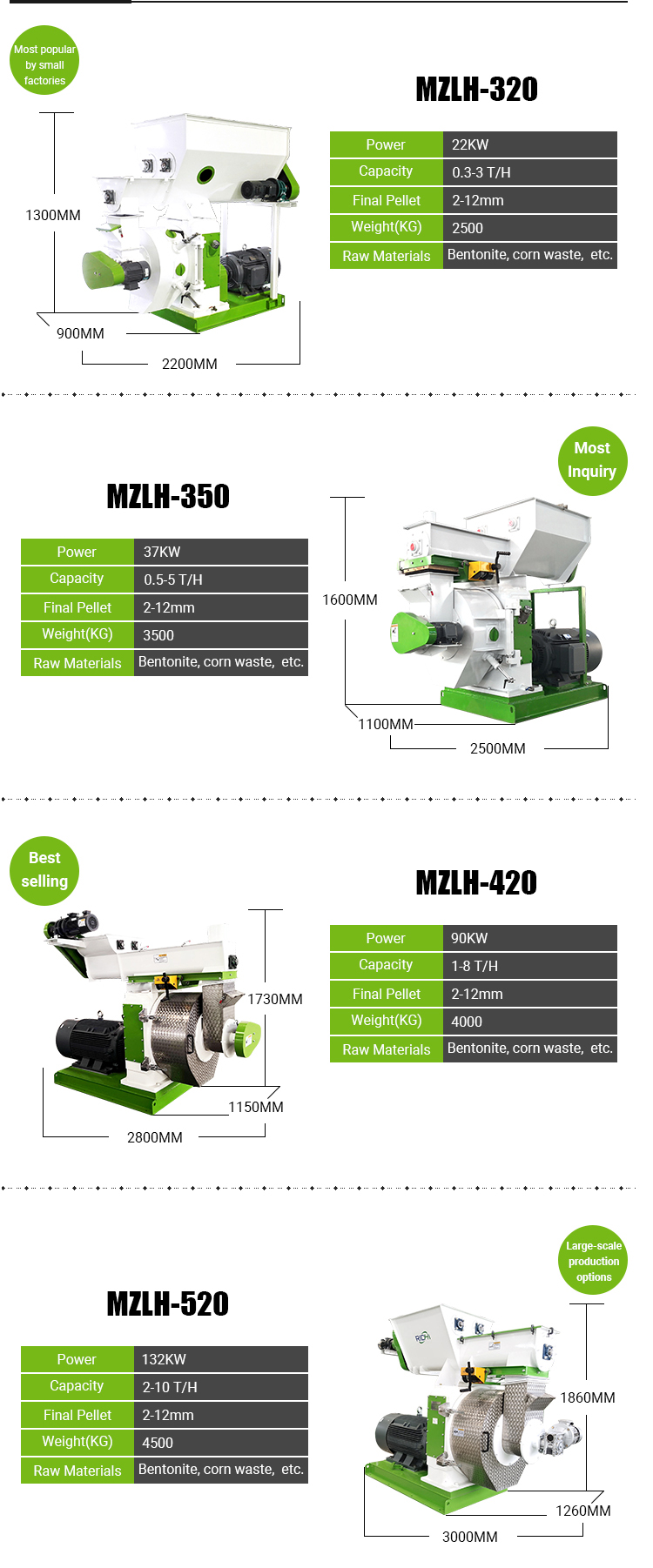

Different Type About RICHI Cat Litter Pellet Machine

RICHI cat litter pellet machine has a lot of different type and capacity, you can choose the suitable type according to your budget and requirement.

Then we can provide the detail informations for you reference.

RICHI Machinery

Why our customer will choose RICHI machinery?

First:Professional, As a professional feed machinery manufacturer with 27 years of experience, RICHI machinery is committed to providing custom ers with turnkey project solutions for feed production project . Provide customers with professional and convenient turnkey engineering services from customer consultation, proposal design, equipment production, product testing, equipment delivery, civil installation, training guidance, technical services, etc.

Second:Service, pre-sale service, our engineer will according customer requirement,workshop size,land size and others to design the suitable design, our engineer and sales revised 14 versions of the design for the client. On-purchase service, Our production department and after-sales department will timely update the production progress and pictures to customers, and at the same time do production testing for customers. After-service, we will provide all the install drawings and equipment list,and will arrange the install engineers to guide customer installation and production train.

Thirdly:Strength, The project covers 121 countries around the world, If you need to, you can always check out our programs in your country. More than 30,000㎡ of modern workshop, CE/ISO and other international certification, 27 patent certificates. We have enough strength to build projects for you.